We spend most of our lives indoors, breathing air circulated by complex HVAC systems. Over time, these systems become reservoirs for dust, mold, bacteria, and allergens. This contamination degrades indoor air quality (IAQ), impacting health, comfort, and even system efficiency. A professionally executed central air conditioning system purification project is not a luxury; it's a critical investment for any facility manager concerned with occupant well-being and operational integrity. This process involves a thorough cleaning, disinfection, and sometimes upgrade of the entire air distribution network.

For businesses, hospitals, hotels, and factories, poor IAQ can lead to tangible losses—increased absenteeism, reduced productivity, and potential liability. This is where specialist intervention becomes essential. Companies like TAI JIE ER leverage industry-specific expertise to transform contaminated HVAC systems into clean, efficient components of a healthy building environment.

The air conditioning system is the lungs of your building. It draws in air, conditions it, and distributes it to every room. If the "lungs" are dirty, the entire "body" suffers.

Addressing this requires a systematic, engineering-led approach, not just a superficial cleaning.

A comprehensive central air conditioning system purification project specifically aims to remove or neutralize several key contaminants.

Particulate Matter (Dust, Pollen, Fibers): These settle in ducts and are constantly recirculated, aggravating allergies and respiratory conditions.

Microbial Contaminants (Mold, Bacteria, Viruses): Perhaps the most significant health threat. Biofilms on wet surfaces can release spores and endotoxins into the airstream.

Volatile Organic Compounds (VOCs): These gases from cleaning agents, furnishings, and building materials can be absorbed into dust within ducts and slowly re-emitted.

A successful project follows a strict protocol to ensure safety, thoroughness, and long-lasting results. TAI JIE ER adheres to international standards, deploying a multi-stage process.

The process begins with diagnosis, not action. Technicians conduct a visual inspection using specialized tools.

Ductwork Videoscopy: Cameras are inserted into ducts to document the level and type of contamination, providing before-and-after evidence.

Air and Surface Sampling: Swab and air samples may be taken to identify specific microbial species, guiding the selection of biocides and disinfectants.

System Mapping: The entire HVAC layout is reviewed to plan access and ensure every component is addressed.

Containing the work area prevents cross-contamination to clean zones during the central air conditioning system purification project.

Negative Air Pressure: HEPA-filtered negative air machines are used to isolate work zones, ensuring all loosened contaminants are captured.

Mechanical Agitation and Vacuuming: High-powered truck-mounted or portable HEPA vacuum collection systems are connected to the ductwork. Agitation tools dislodge stubborn debris, which is immediately extracted.

Component Cleaning: Fan coils, drain pans, grilles, and diffusers are meticulously hand-cleaned and sanitized.

After physical debris is removed, the next step is microbial control.

Application of EPA-Approved Biocides: Non-toxic, antimicrobial agents are applied via fogging or spraying to coat interior surfaces, eliminating remaining mold and bacteria.

Oxidation and Sealing: In some cases, ultraviolet-C (UV-C) light systems may be recommended for ongoing disinfection at the coil, or sealants may be applied to encapsulate minor residual debris on pitted surfaces.

A thorough cleaning resets the system. Integrating modern purification technologies helps keep it clean and enhances overall IAQ performance.

High-Efficiency Particulate Air (HEPA) Filtration: Upgrading final filters to HEPA-grade can capture over 99.97% of particles down to 0.3 microns.

Ultraviolet Germicidal Irradiation (UVGI): Installing UV-C lamps near cooling coils and in return air ducts provides continuous disinfection, preventing microbial regrowth.

Photocatalytic Oxidation (PCO) Systems: These advanced units can break down gaseous pollutants (VOCs) and odors at a molecular level, offering a higher level of air purification.

IAQ Monitoring Sensors: Installing real-time monitors for CO2, PM2.5, and VOCs provides data-driven proof of air quality improvement and can trigger system adjustments.

The return on investment from a central air conditioning system purification project varies by industry but is always significant.

Healthcare Facilities: Critical for preventing Hospital-Acquired Infections (HAIs) and protecting immunocompromised patients. It's a core component of infection control protocols.

Commercial Offices: Leads to fewer employee sick days, improved cognitive function, and enhanced overall comfort. It directly supports employee wellness initiatives.

Hospitality Industry: Creates a fresher, cleaner guest experience, reduces musty odors in rooms, and can be a powerful marketing point for health-conscious travelers.

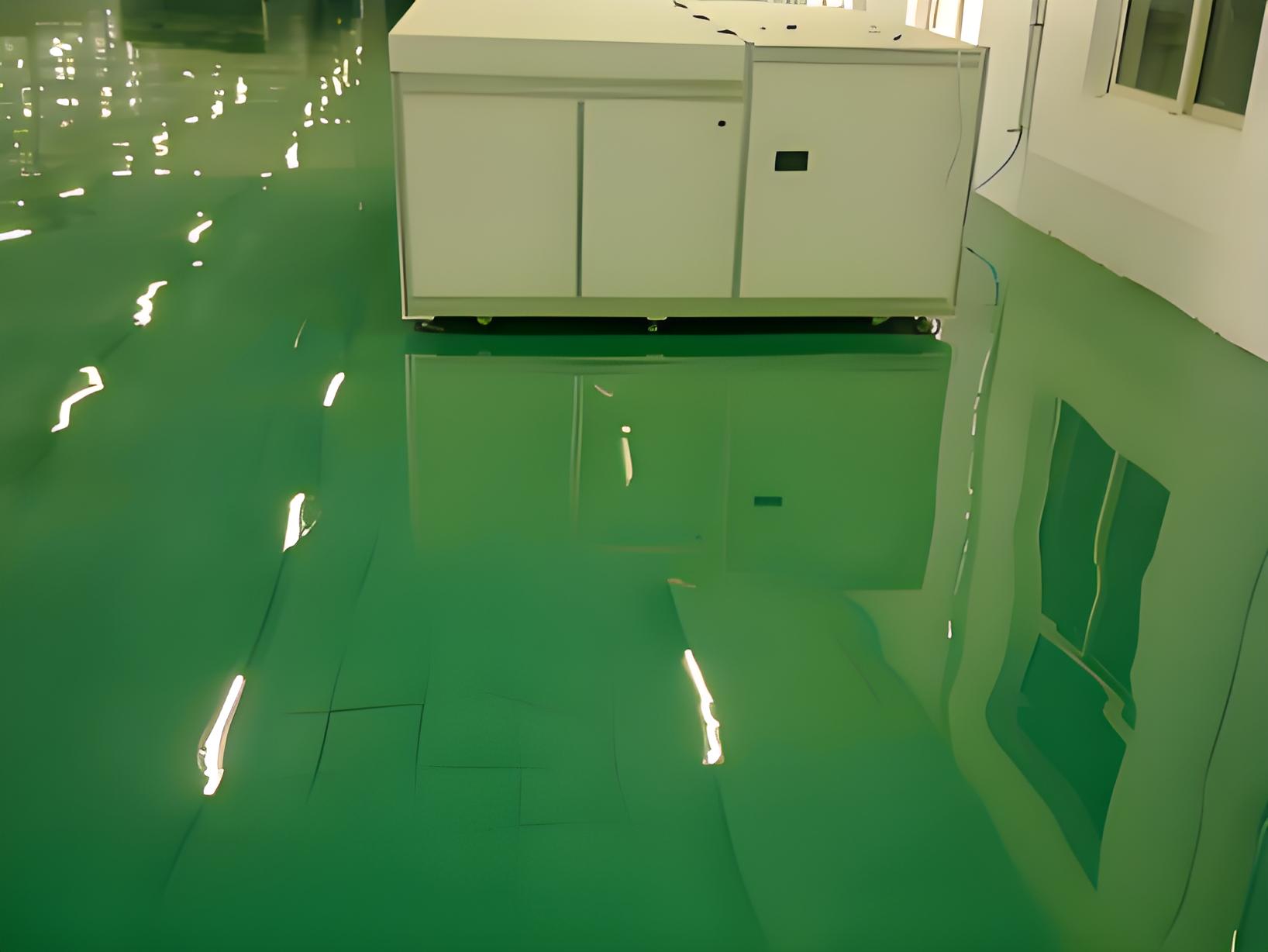

Manufacturing & Cleanrooms: Essential for process control, product integrity, and meeting stringent ISO classifications by eliminating airborne particles that can ruin sensitive production.

A 15-story office tower in the city center was experiencing persistent complaints of stale air and increased allergy symptoms among tenants. TAI JIE ER was commissioned to undertake a full-scale purification project.

The project began with videoscopic inspection, revealing significant dust buildup and visible mold on several cooling coils in the air handling units.

The team executed night-shift work to avoid business disruption. They implemented full containment on each floor, performed aggressive HEPA vacuuming of over 20,000 linear feet of ductwork, and cleaned all 150+ fan coil units.

Post-cleaning, a safe, dry disinfectant was fogged throughout the system. TAI JIE ER also recommended and installed UV-C lights in the main AHUs to prevent future microbial growth.

Post-project air testing showed a 90% reduction in airborne particulate counts. Tenant complaints ceased, and building management reported a noticeable improvement in perceived air freshness, validating the critical need for such specialized maintenance.

Choosing the right partner is as important as the decision to purify. Look for certified technicians, adherence to NADCA (National Air Duct Cleaners Association) or equivalent standards, transparent pricing, and a robust post-project reporting process.

Q1: How often should a commercial central air conditioning system undergo a purification project?

A1: The frequency depends on the building type, location, and system usage. Generally, a comprehensive project is recommended every 3 to 5 years. Hospitals, laboratories, or facilities in high-pollution areas may require more frequent service, such as every 2 years. Regular annual inspections can help determine the optimal schedule.

Q2: Does the purification process use harsh chemicals that could be hazardous to occupants?

A2: Reputable providers like TAI JIE ER use EPA-registered, hospital-grade disinfectants and biocides that are safe for occupied spaces when applied correctly. These products are typically non-toxic and dry to an inert state. Safety Data Sheets (SDS) are always available for review, and application is performed under strict containment protocols.

Q3: Will the cleaning process disrupt our daily business operations?

A3: A well-planned project minimizes disruption. Much of the work can be scheduled for nights, weekends, or during off-peak hours. Technicians use containment barriers and negative air machines to isolate work areas, allowing normal operations to continue in other parts of the building. A clear phasing plan is developed before work begins.

Q4: Can air duct cleaning help reduce our energy bills?

A4: Absolutely. A layer of dust and grime on cooling coils acts as an insulator, forcing the system to work harder and longer to achieve the set temperature. Removing this buildup improves heat transfer efficiency. Similarly, clean ductwork reduces airflow resistance. These improvements can lead to measurable energy savings, often between 10-20% on cooling costs.

Q5: What certifications should we look for when hiring a purification service provider?

A5: Key certifications include the NADCA Air Systems Cleaning Specialist (ASCS) certification, which indicates trained personnel. The company should also carry relevant insurance (liability and workers' compensation). Membership in professional bodies like NADCA or IEI (Indoor Environment International) shows a commitment to industry standards. Always ask for proof of certifications and references.