In the modern industrial landscape, air quality is no longer a luxury—it is a critical requirement for both human health and manufacturing precision. A well-executed central air conditioning system purification project does more than just regulate temperature; it acts as the primary defense against airborne contaminants, pathogens, and fine particulates. For sectors such as pharmaceuticals, semiconductor manufacturing, and healthcare, the integration of advanced filtration and sterilization within the HVAC infrastructure is a non-negotiable standard.

TAI JIE ER has observed a significant shift in how global enterprises approach indoor environmental quality. Companies are moving away from basic ventilation and toward comprehensive purification systems that integrate seamlessly with existing building management software. This transition ensures that the air circulated within a facility remains within strict microbial and particulate limits, regardless of external environmental conditions.

Every successful central air conditioning system purification project begins with a thorough site assessment. Engineers must evaluate the existing ductwork, the capacity of the current air handling units (AHUs), and the specific cleanliness class required by the facility's operations. This initial phase determines whether a retrofit is possible or if a complete system overhaul is necessary to meet ISO or ASHRAE standards.

TAI JIE ER emphasizes that air purification is a multi-stage process. It involves pre-filtration to capture large debris, followed by high-efficiency particulate air (HEPA) filters for microscopic particles, and often includes ultraviolet germicidal irradiation (UVGI) to neutralize biological threats. Each component must be sized correctly to prevent excessive pressure drops, which can lead to increased energy consumption and mechanical wear.

When planning a central air conditioning system purification project, stakeholders often weigh the pros and cons of different technologies. Mechanical filtration remains the gold standard for particulate removal. HEPA filters, rated to capture 99.97% of particles as small as 0.3 microns, are the backbone of cleanroom engineering. However, they require powerful fans to overcome the resistance they create in the airflow.

Electronic air cleaners or electrostatic precipitators offer an alternative. These systems charge incoming particles and collect them on oppositely charged plates. While they offer lower air resistance, they require frequent cleaning and may produce trace amounts of ozone, which must be managed. TAI JIE ER often recommends a hybrid approach, combining mechanical filters with photo-catalytic oxidation (PCO) to tackle both particulate matter and volatile organic compounds (VOCs).

In the field of international cleanroom engineering, compliance with ISO 14644 standards is paramount. A central air conditioning system purification project must be designed to maintain specific pressure differentials between rooms. This prevents "cross-contamination," where air from a lower-cleanliness area migrates into a high-precision zone.

Positive pressure is typically maintained in the cleanest areas to ensure that when doors are opened, air flows out rather than in. The HVAC system must be capable of precise air change rates (ACR), which can range from 20 to over 600 changes per hour depending on the cleanliness class. TAI JIE ER integrates smart sensors into these projects to monitor these variables in real-time, allowing for automated adjustments that maintain the environment within the desired parameters.

The requirements for a central air conditioning system purification project vary significantly between a hospital and a semiconductor plant. In healthcare settings, the focus is primarily on infection control. This requires specialized exhaust systems and HEPA filtration to trap bacteria and viruses. The system must also manage humidity levels to prevent the growth of mold within the ductwork.

In contrast, the electronics industry focuses on "molecular contamination." Even a single dust particle can ruin a silicon wafer. Here, the purification project must address chemical outgassing and static electricity. TAI JIE ER utilizes advanced chemical filters and ionization bars integrated into the AHUs to ensure that the air is not only clean but also chemically neutral and stable.

At TAI JIE ER, we approach every central air conditioning system purification project with a focus on durability and efficiency. Our engineering process starts with Computational Fluid Dynamics (CFD) modeling. This allows us to visualize how air will move through a space before a single piece of equipment is installed. By identifying "dead zones" where air stagnates, we can optimize the placement of diffusers and return vents.

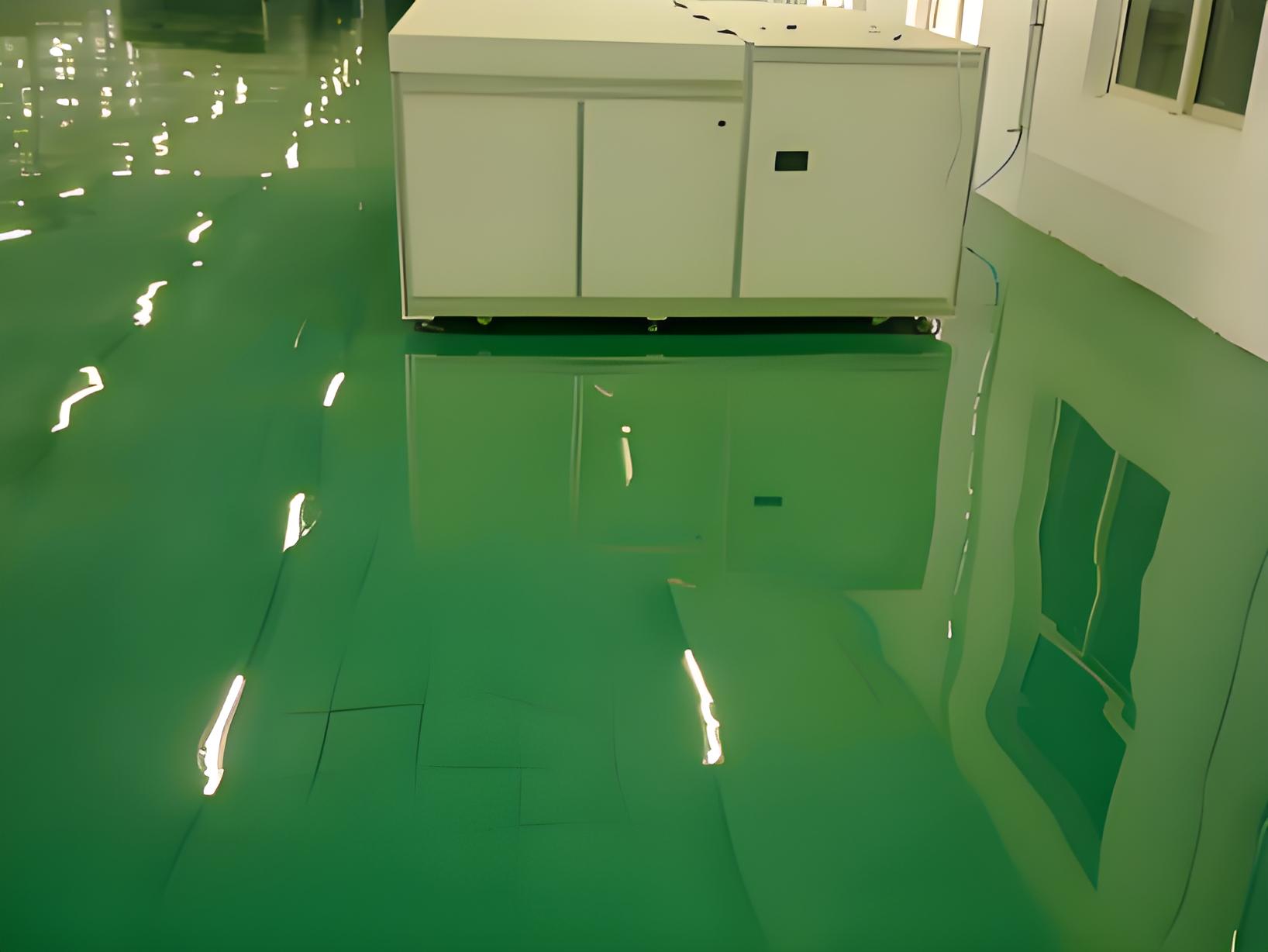

Quality control during the installation phase is equally important. Ductwork must be sealed to prevent leaks that could bypass the filtration stages. We use medical-grade sealants and ensure that all internal surfaces of the HVAC system are smooth to prevent the accumulation of dust. This attention to detail ensures that the system performs as expected during the final validation and commissioning stages.

One of the biggest challenges in any central air conditioning system purification project is the energy demand. High-efficiency filters and high air change rates require significant power. To mitigate this, TAI JIE ER implements Variable Frequency Drives (VFDs) on all fan motors. This allows the system to scale its output based on real-time occupancy and air quality readings.

Heat recovery ventilation (HRV) is another critical component. By capturing the thermal energy from the exhaust air and using it to pre-condition the fresh incoming air, facilities can reduce their heating and cooling loads by up to 30%. This not only lowers operational costs but also aligns the facility with global sustainability goals.

The hand-over of a central air conditioning system purification project is just the beginning. Without a rigorous maintenance schedule, even the most advanced system will eventually fail to meet its cleanliness targets. Filters must be monitored via pressure differential gauges; when the pressure drop across a filter exceeds a certain threshold, it must be replaced to prevent air bypass and strain on the blowers.

TAI JIE ER provides comprehensive training for on-site facility managers and offers remote monitoring services. Regular duct cleaning and UV lamp replacement are essential parts of the lifecycle management of the system. By maintaining the integrity of the purification stages, the facility can avoid costly production shutdowns or health-related liabilities.

Choosing a contractor for a central air conditioning system purification project requires a balance of technical expertise and practical experience. It is important to look for a partner who understands the specific regulatory environment of your industry. A provider should be able to offer a turnkey solution, from initial design and CAD drawings to installation, testing, and certification.

TAI JIE ER has built a reputation for delivering high-performance air purification systems that stand the test of time. We prioritize transparency in our pricing and provide detailed documentation for every project phase. Our goal is to create environments where technology and biology can coexist without interference from airborne contaminants.

The integration of the Internet of Things (IoT) has revolutionized how we manage a central air conditioning system purification project. Modern systems are equipped with PM2.5 sensors, CO2 monitors, and TVOC (Total Volatile Organic Compound) detectors. These devices feed data into a centralized control hub, which can be accessed via mobile devices or desktop computers.

This level of connectivity allows for predictive maintenance. Instead of replacing filters on a fixed schedule, the system can notify the manager when the filter's performance actually starts to decline. TAI JIE ER uses this data-driven approach to help clients optimize their filter inventory and reduce unnecessary waste, further enhancing the project's return on investment.

In conclusion, investing in a professional central air conditioning system purification project is a strategic move for any business that values operational excellence and safety. From the selection of high-grade HEPA filters to the implementation of smart control systems, every step must be handled with precision. By partnering with an experienced firm like TAI JIE ER, you ensure that your facility meets international standards while maintaining energy efficiency. A well-designed system does not just clean the air; it provides the foundation for a productive, healthy, and compliant industrial environment.

Q1: What is the primary difference between standard HVAC and a central air conditioning system purification project?

A1: A standard HVAC system focuses mainly on temperature and humidity control for comfort. A purification project adds specialized layers of filtration (like HEPA or ULPA), sterilization (UVGI), and air pressure management to remove microscopic contaminants and pathogens, making it suitable for cleanrooms and sterile environments.

Q2: How often should HEPA filters be replaced in these systems?

A2: There is no fixed timeline, as it depends on the air quality of the environment. However, TAI JIE ER recommends monitoring the pressure differential. Typically, in a well-maintained industrial setting, HEPA filters are replaced every 12 to 24 months, while pre-filters are replaced every 3 to 6 months to extend the life of the main filters.

Q3: Can an existing central air conditioning system be retrofitted for purification?

A3: Yes, many systems can be retrofitted. However, the existing fans must be checked to ensure they can handle the increased static pressure caused by high-efficiency filters. TAI JIE ER specializes in assessing older systems and integrating modern purification modules without requiring a complete demolition of the existing infrastructure.

Q4: What ISO classes do your purification projects typically achieve?

A4: Our projects are designed to meet a wide range of requirements, from ISO Class 8 (standard cleanroom) down to ISO Class 1 (ultra-clean environments). The design of the central air conditioning system purification project is tailored specifically to the class required by the client’s industry and local regulations.

Q5: Does air purification significantly increase energy bills?

A5: While higher filtration levels require more power, the use of energy-efficient fans, Variable Frequency Drives (VFDs), and smart sensors can offset these costs. TAI JIE ER focuses on optimizing the airflow design to reduce resistance, ensuring that the system remains as cost-effective as possible over its lifespan.

Q6: Are UV lights necessary in a central air conditioning system purification project?

A6: UVGI (Ultraviolet Germicidal Irradiation) is highly recommended for facilities where biological contamination is a risk, such as food processing or hospitals. While HEPA filters trap bacteria, UV lights neutralize them, preventing the growth of biofilms on the cooling coils and within the ductwork.