In today's world, where indoor air quality is increasingly linked to health and productivity, a central air conditioning system purification project has become a critical initiative for many businesses and homeowners. This type of project focuses on enhancing the performance and safety of HVAC systems by integrating advanced purification technologies. Whether for commercial buildings, industrial facilities, or specialized environments like cleanrooms, such projects aim to remove contaminants, improve energy efficiency, and ensure compliance with health standards. As concerns over airborne pollutants and viruses grow, investing in a comprehensive purification strategy is no longer optional but essential. This article delves into the key components, benefits, and processes involved in these projects, highlighting how they contribute to sustainable and healthy indoor environments.

A central air conditioning system purification project involves a systematic approach to cleaning and optimizing the air handling units, ducts, and components of an HVAC system. This project typically starts with an assessment of the existing system to identify contamination levels, such as dust, mold, bacteria, or volatile organic compounds (VOCs). The goal is to implement solutions that not only purify the air but also extend the system's lifespan and reduce operational costs. For instance, in large buildings, this might include installing high-efficiency particulate air (HEPA) filters, UV germicidal irradiation, or photocatalytic oxidation units. By addressing both particulate and microbial contaminants, a central air conditioning system purification project ensures that the air circulated is clean and safe, which is particularly vital in settings like hospitals, schools, and offices where air quality directly impacts occupant well-being.

Moreover, such projects often integrate with broader building management systems, allowing for real-time monitoring and control. This holistic approach helps in maintaining consistent air quality while adapting to changing environmental conditions. For example, in a central air conditioning system purification project, sensors can detect spikes in pollutants and automatically adjust purification settings, ensuring optimal performance without manual intervention. This not only enhances indoor air quality but also supports energy conservation by preventing overuse of resources. As regulations tighten and awareness increases, embarking on a central air conditioning system purification project has become a proactive step for property managers aiming to meet modern health and sustainability standards.

An HVAC purification system is at the heart of any central air conditioning system purification project, serving as the primary mechanism for removing harmful elements from the air. These systems are designed to work seamlessly with existing HVAC infrastructure, incorporating technologies like electrostatic precipitators, carbon filters, and ionizers to capture and neutralize contaminants. In commercial settings, an effective HVAC purification system can reduce the spread of allergens and pathogens, leading to fewer sick days and higher productivity. For instance, in office environments, where air is recirculated frequently, a robust HVAC purification system can trap fine particles and microbes, preventing them from accumulating in ductwork and causing long-term issues.

Additionally, the integration of an HVAC purification system supports environmental sustainability by minimizing the release of pollutants and reducing the energy required for heating and cooling. Many modern systems are designed with smart controls that optimize performance based on air quality metrics, making them a key component in green building certifications. In the context of a central air conditioning system purification project, selecting the right HVAC purification system involves evaluating factors like filter efficiency, maintenance requirements, and compatibility with existing equipment. This ensures that the system not only purifies the air effectively but also operates efficiently over time, providing long-term benefits for both occupants and building owners.

When it comes to manufacturing plants, warehouses, and other industrial settings, industrial air system purification is a specialized aspect of a central air conditioning system purification project. These environments often face unique challenges, such as high levels of dust, fumes, or chemical vapors, which require heavy-duty purification solutions. An industrial air system purification setup typically includes features like industrial-grade filters, scrubbers, and ventilation systems that can handle large air volumes and harsh conditions. For example, in a factory producing electronic components, industrial air system purification might involve electrostatic filters to capture microscopic particles that could damage sensitive equipment.

Furthermore, industrial air system purification plays a crucial role in worker safety and regulatory compliance. By effectively removing hazardous substances, these systems help prevent respiratory issues and meet occupational safety standards. In a comprehensive central air conditioning system purification project, the industrial air system purification component is often customized to address specific contaminants found in the facility, such as oil mists in machining areas or chemical residues in laboratories. This tailored approach ensures that the purification process is both efficient and cost-effective, contributing to a safer and more productive work environment. As industries evolve, incorporating advanced industrial air system purification technologies has become essential for maintaining competitive advantage and adhering to environmental regulations.

Selecting reputable HVAC purification companies is a critical step in executing a successful central air conditioning system purification project. These companies bring expertise in design, installation, and maintenance, ensuring that the purification system meets the specific needs of the building or facility. When evaluating HVAC purification companies, it's important to consider their experience, certifications, and track record with similar projects. For instance, a company specializing in commercial HVAC purification system installations might offer tailored solutions that include energy audits and compliance checks, which are vital for long-term performance.

Moreover, partnering with skilled HVAC purification companies can provide access to the latest technologies and best practices. Many top-tier HVAC purification companies offer comprehensive services, from initial consultation to ongoing support, including regular filter replacements and system upgrades. In a central air conditioning system purification project, this partnership ensures that the purification components are integrated smoothly with the existing HVAC infrastructure, minimizing disruptions and maximizing efficiency. Additionally, HVAC purification companies often provide training for building staff, empowering them to manage the system effectively. By choosing the right HVAC purification companies, stakeholders can achieve a seamless project execution that delivers lasting benefits in air quality and operational savings.

The HVAC System Purification process is a methodical part of any central air conditioning system purification project, involving several stages to ensure thorough cleaning and optimization. It typically begins with a detailed inspection and testing phase, where professionals assess the current state of the HVAC system, including ductwork, coils, and filters. This helps identify contamination hotspots and determine the appropriate purification methods. For example, in HVAC System Purification, techniques like air duct cleaning, coil sterilization, and filter upgrades are commonly used to remove accumulated debris and microbial growth.

Next, the implementation phase involves installing purification devices and integrating them with the HVAC controls. This might include adding UV lights to disinfect air streams or incorporating advanced filtration systems that capture ultrafine particles. Throughout this process, HVAC System Purification focuses on enhancing air flow and reducing energy consumption, which aligns with the goals of a central air conditioning system purification project. Regular monitoring and maintenance are also key components of HVAC System Purification, as they ensure that the system continues to operate at peak efficiency. By following a structured HVAC System Purification approach, building owners can achieve significant improvements in indoor air quality, leading to healthier environments and lower utility costs over time.

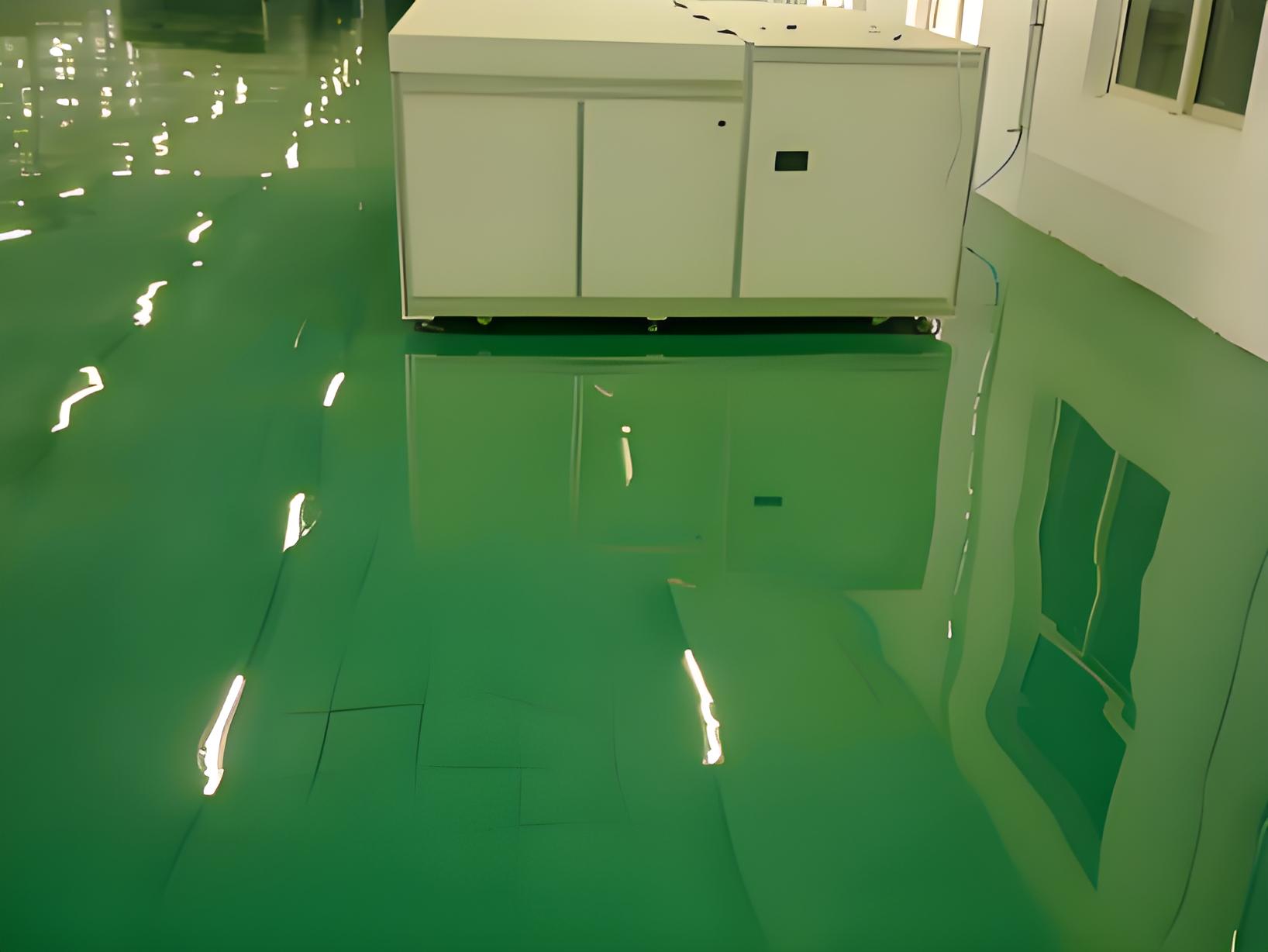

In highly controlled settings like pharmaceuticals, biotechnology, and electronics manufacturing, Cleanroom HVAC Commissioning & Validation is an essential element of a central air conditioning system purification project. This process ensures that the HVAC system in a cleanroom meets strict regulatory standards for air purity, temperature, humidity, and pressure differentials. Cleanroom HVAC Commissioning & Validation involves rigorous testing and documentation to verify that the system performs as intended, preventing contamination that could compromise sensitive processes. For instance, in a pharmaceutical cleanroom, Cleanroom HVAC Commissioning & Validation might include particle counting, airflow visualization, and filter integrity tests to maintain sterile conditions.

Furthermore, Cleanroom HVAC Commissioning & Validation is not a one-time event but an ongoing practice that requires periodic re-validation to adapt to changes in operations or regulations. Within a central air conditioning system purification project, this component demands collaboration among engineers, validation specialists, and quality assurance teams to ensure compliance with standards like ISO 14644. By incorporating Cleanroom HVAC Commissioning & Validation, facilities can achieve reliable performance, reduce product loss, and protect their reputations. This makes it a vital investment for industries where even minor deviations in air quality can have significant consequences, underscoring the importance of integrating Cleanroom HVAC Commissioning & Validation into broader purification initiatives.

A central air conditioning system purification project is a multifaceted endeavor that addresses critical aspects of indoor air quality, system efficiency, and regulatory compliance. By incorporating elements like an HVAC purification system, industrial air system purification, and Cleanroom HVAC Commissioning & Validation, these projects offer comprehensive solutions for various environments. Partnering with experienced HVAC purification companies ensures that the HVAC System Purification process is executed effectively, leading to long-term benefits such as improved health outcomes, reduced energy costs, and enhanced operational reliability. As awareness of air quality issues grows, investing in such projects becomes increasingly important for creating sustainable and safe indoor spaces. Whether for commercial, industrial, or specialized applications, a well-planned central air conditioning system purification project can transform how we experience and manage our built environments.

Q1: What is a central air conditioning system purification project, and why is it important?

A1: A central air conditioning system purification project involves cleaning and enhancing the air quality within HVAC systems through methods like filtration, sterilization, and monitoring. It is important because it improves indoor air quality by removing contaminants such as dust, mold, and bacteria, which can lead to health benefits, increased energy efficiency, and compliance with safety standards. This project is crucial in settings like offices, hospitals, and industrial facilities to ensure a healthy environment and extend the lifespan of the HVAC equipment.

Q2: How does an HVAC purification system integrate with existing air conditioning systems?

A2: An HVAC purification system integrates with existing air conditioning systems by being installed within the ductwork, air handlers, or other components to purify the air as it circulates. Technologies like HEPA filters, UV lights, or ionizers are added to capture or neutralize pollutants without major modifications. This integration is designed to be seamless, often involving smart controls that adjust purification levels based on real-time air quality data, ensuring optimal performance alongside the central air conditioning system.

Q3: What are the key benefits of industrial air system purification in manufacturing plants?

A3: The key benefits of industrial air system purification in manufacturing plants include enhanced worker safety by reducing exposure to hazardous fumes and particles, improved product quality by minimizing contamination, and compliance with environmental regulations. It also boosts operational efficiency by preventing equipment clogging and reducing maintenance costs. In the context of a central air conditioning system purification project, this specialized purification helps maintain a clean production environment, leading to higher productivity and lower health risks.

Q4: How do I choose the right HVAC purification companies for my project?

A4: To choose the right HVAC purification companies, consider factors such as their experience with similar projects, certifications (e.g., from ASHRAE or NADCA), customer reviews, and the range of services they offer, including design, installation, and maintenance. It's also important to evaluate their expertise in specific areas like HVAC System Purification or Cleanroom HVAC Commissioning & Validation. Requesting case studies and quotes can help you compare options and select a company that aligns with your budget and project goals for a central air conditioning system purification project.

Q5: What is involved in Cleanroom HVAC Commissioning & Validation, and how often should it be done?

A5: Cleanroom HVAC Commissioning & Validation involves testing and verifying that the HVAC system in a cleanroom meets predefined standards for air purity, temperature, humidity, and pressure. This includes activities like particle counting, airflow testing, and filter integrity checks, followed by detailed documentation. It should be performed initially after installation and then periodically, typically annually or after any significant changes to the system, as part of a central air conditioning system purification project to ensure ongoing compliance and performance in sensitive environments like labs or production facilities.

This article provides an in-depth look at central air conditioning system purification projects, covering essential aspects like HVAC purification systems, industrial air system purification, and more. If you're planning a project, consult with professionals to tailor solutions to your specific needs.