In today's world, where air quality and contamination control are paramount in industries like pharmaceuticals, biotechnology, semiconductors, and healthcare, the Central air conditioning system purification project has become a cornerstone of facility management. This comprehensive process goes far beyond simple temperature control; it is a sophisticated engineering endeavor designed to create and maintain pristine environments. Such projects are intrinsically linked to the specialized field of Cleanroom HVAC System Engineering, which focuses on integrating precision air handling, filtration, and environmental control to meet stringent regulatory and operational standards. The success of any critical environment hinges on flawless Cleanroom HVAC System Design and Integration, a multidisciplinary approach that merges architectural, mechanical, and control systems into a single, cohesive unit. This article delves deep into the intricacies of the design and integration of critical cleanroom HVAC systems, explores common challenges, and highlights the advantages of opting for Turnkey Cleanroom HVAC Solutions.

A Central air conditioning system purification project is a large-scale initiative aimed at overhauling or installing an HVAC system with the primary goal of purifying and controlling the indoor air to exceptionally high standards. Unlike conventional HVAC, which focuses on comfort, these projects are designed for precision, controlling particulate count, temperature, humidity, air pressure, and airflow patterns. The core objective is to create a stable, predictable environment that is immune to external contaminants and internal particle generation. This is achieved through a multi-stage process involving rigorous planning, expert Cleanroom HVAC System Engineering, and meticulous execution. The scope of such a project typically includes advanced filtration (like HEPA and ULPA filters), precise humidity and temperature control, and sophisticated monitoring and control systems.

Cleanroom HVAC System Engineering is the technical foundation upon which every successful Central air conditioning system purification project is built. It is a specialized discipline that applies engineering principles to design systems that can achieve and maintain specific cleanliness classifications, as defined by standards like ISO 14644.

Key engineering considerations include:

Airflow Design: Engineering laminar or turbulent airflow patterns to sweep particles away from critical zones. Unidirectional laminar flow is often used in the most sensitive environments.

Filtration Strategy: Selecting and positioning pre-filters, secondary filters, and terminal HEPA/ULPA filters to achieve the required particulate removal efficiency (e.g., 99.97% or 99.999% for particles as small as 0.3 microns).

Pressurization Control: Designing a cascade of air pressure differentials between adjacent rooms to prevent cross-contamination. Cleaner rooms are maintained at a higher pressure.

Thermal Load Calculation: Precisely calculating heat gains from people, equipment, and processes to size cooling and heating coils appropriately, ensuring strict temperature stability (±0.5°C or better).

Humidity Control: Specifying humidification and dehumidification equipment to maintain tight relative humidity setpoints, crucial for preventing static electricity, microbial growth, and product spoilage.

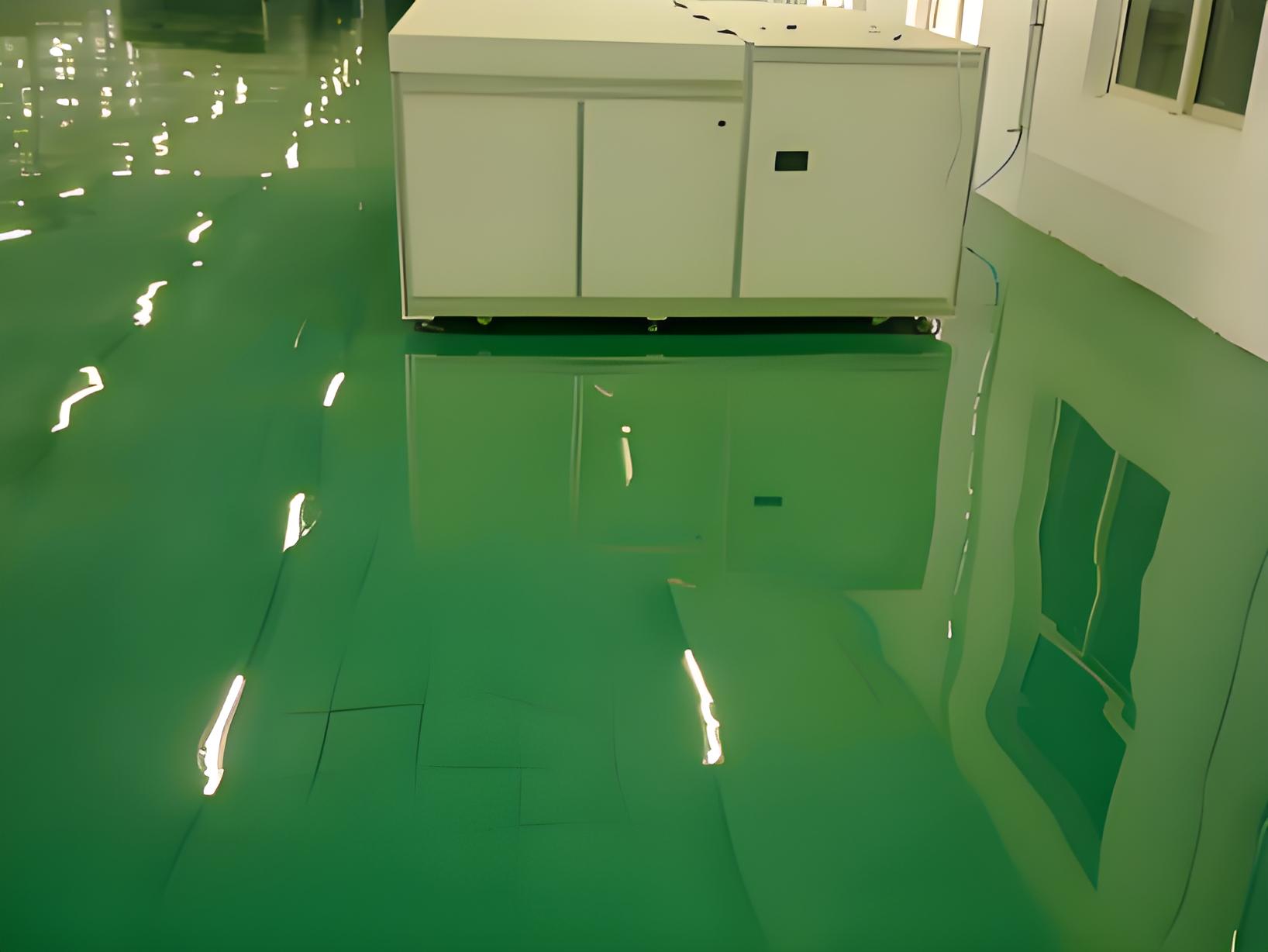

The Cleanroom HVAC System Design and Integration phase is where the engineering plans are translated into a functional, interoperable system. This is arguably the most critical phase of a Central air conditioning system purification project. Design and integration must consider the entire ecosystem of the cleanroom, not just the air handler.

The process involves:

Conceptual and Detailed Design: Creating detailed schematics, layouts, and specifications for all components, including air handling units (AHUs), ductwork, dampers, sensors, and control panels.

Component Integration: Seamlessly combining the HVAC system with other critical cleanroom components, such as insulated panels, ceilings, lighting, and gowning areas. The ductwork must be designed to integrate flawlessly with the HEPA filter housings in the cleanroom ceiling or walls.

Control System Integration: The brain of the operation. A Building Management System (BMS) or Building Automation System (BAS) is integrated to monitor and control every parameter—temperature, humidity, pressure, fan speed, and filter status—in real-time, providing alerts and data logging for compliance.

Commissioning: A rigorous process of testing and verifying that every component and the system as a whole performs according to the design intent and project specifications.

The design and integration of critical cleanroom HVAC systems presents unique challenges that require expert knowledge. Several non-negotiable factors must be addressed:

Redundancy: Critical systems often include N+1 or even 2N redundancy for fans, cooling systems, and power supplies to ensure uninterrupted operation in case of a component failure.

Materials of Construction: All materials within the airstream, including ducts, coils, and drain pans, must be non-shedding, corrosion-resistant, and easy to clean (e.g., stainless steel or coated carbon steel).

Airtightness: Ductwork and room enclosures must be exceptionally airtight to prevent leakage that could compromise pressure differentials and filtration efficiency.

Energy Efficiency: Given the high airflow rates and precise conditioning requirements, these systems are energy-intensive. Design must incorporate energy recovery wheels, variable frequency drives (VFDs) on motors, and optimized control sequences to reduce operational costs.

Regulatory Compliance: The system must be designed to meet the stringent requirements of agencies like the FDA (cGMP), EMA, and other international standards.

For many organizations, managing a Central air conditioning system purification project in-house can be overwhelming due to its complexity. This is where Turnkey Cleanroom HVAC Solutions offer a significant advantage. A turnkey provider acts as a single point of responsibility, managing the project from initial concept and design through procurement, installation, commissioning, and validation.

Benefits of a turnkey approach include:

Single Point of Accountability: One contractor is responsible for the entire system, eliminating finger-pointing between separate design, installation, and controls firms.

Streamlined Project Management: The turnkey provider handles all scheduling, coordination, and communication, reducing the administrative burden on the client.

Cost and Time Certainty: With a fixed scope and single responsibility, projects are more likely to be completed on time and within budget.

Guaranteed Performance: The provider guarantees that the integrated system will perform as specified, often backed by comprehensive validation and testing protocols (IQ/OQ/PQ).

Expertise and Experience: Turnkey providers bring specialized knowledge from numerous projects, ensuring best practices are followed and potential pitfalls are avoided.

Even with careful planning, projects can encounter problems. Awareness of these common issues is the first step toward mitigation.

Inadequate Contamination Control: This can stem from poor airflow design, incorrect filter selection, or leaks in the ductwork, leading to a failure to meet the target ISO class.

Instability in Environmental Parameters: Fluctuations in temperature and humidity are often caused by improperly sized equipment, poor control logic, or a lack of redundancy in critical components.

Pressure Differential Issues: Failing to maintain proper pressurization is a frequent problem. This can be due to air leakage, imbalanced airflow, or doors being left open, compromising contamination control.

High Energy Consumption: An inefficient design without energy recovery or VFDs can lead to exorbitant operational costs. This is a common oversight in initial designs focused solely on performance.

Validation and Compliance Failures: The system may work but fail to meet regulatory documentation and testing requirements. This highlights the need for early engagement with validation protocols.

Poor Integration and Coordination: If the HVAC system is not perfectly coordinated with the architectural and electrical systems, it can lead to costly field modifications, delays, and performance issues.

A successful Central air conditioning system purification project is a complex symphony of precision engineering, thoughtful design, and flawless integration. It requires a deep understanding of Cleanroom HVAC System Engineering principles and a meticulous approach to the Cleanroom HVAC System Design and Integration process. The challenges in the design and integration of critical cleanroom HVAC systems are significant, but they can be effectively managed and overcome. For organizations looking to ensure success, minimize risk, and guarantee performance, partnering with a provider that offers Turnkey Cleanroom HVAC Solutions is often the most strategic and efficient path forward. By investing in a properly designed and integrated system, businesses can protect their products, processes, and ultimately, their patients and customers, while ensuring regulatory compliance and operational efficiency for years to come.