Building or upgrading a pharmaceutical facility is never just about construction. It is about compliance, safety, and precision. When plant managers and investors look at pharmaceutical purification engineering, they are often balancing strict GMP regulations with tight budgets.

The process involves integrating HVAC systems, specialized architectural materials, and complex piping into a seamless environment. One mistake in pressure differentials or material selection can lead to failed validation and production halts.

This article breaks down the engineering process into practical steps. We will look at real-world applications, cost drivers, and how to select the right partners, including established names like TAI JIE ER, to ensure your facility passes inspection the first time.

Many people confuse general cleanroom construction with pharmaceutical specificities. Pharmaceutical purification engineering goes beyond just installing filters. It is a holistic discipline that manages physical, chemical, and biological contamination.

The primary goal is to create a controlled environment. This limits the concentration of airborne particles. It also strictly controls other parameters like temperature, humidity, and pressure.

In pharmaceutical manufacturing, the scope includes the layout of personnel flow and material flow. Cross-contamination is the enemy. The engineering design must separate raw material entry, production, packaging, and waste exit.

Successful engineering projects prioritize the "static" state (when equipment is installed but not running) and the "dynamic" state (when production is active). The engineering team must calculate airflow patterns to ensure that the cleanroom performs under both conditions.

You cannot discuss this topic without mentioning regulations. The backbone of any pharmaceutical purification engineering project is the Good Manufacturing Practice (GMP) standard.

Different regions have different requirements. The US FDA, EU GMP, and WHO guidelines all share similar principles but differ in validation specifics. For example, the EU GMP Annex 1 was recently updated, placing heavier emphasis on Contamination Control Strategy (CCS).

Engineers must align the facility design with ISO 14644-1 classifications.

ISO 5 (Class 100): Required for critical aseptic processing (filling zones).ISO 7 (Class 10,000): Common for surrounding areas.ISO 8 (Class 100,000): Used for non-sterile manufacturing steps.

If your engineering partner does not have deep knowledge of these specific clauses, your facility risk audit failure. The design phase must generate the necessary documentation (DQ - Design Qualification) to support later validation stages (IQ, OQ, PQ).

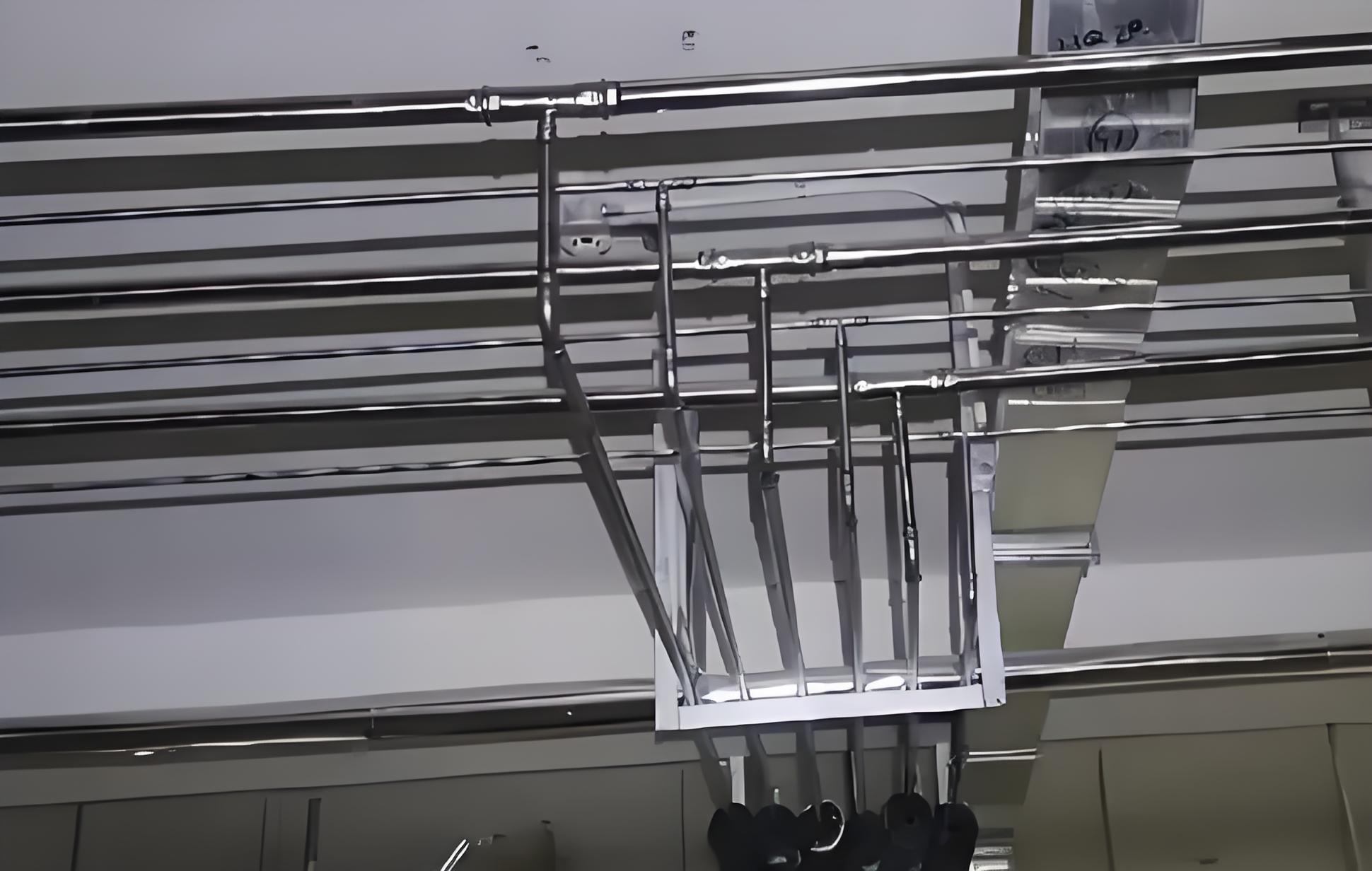

The HVAC system is the lungs of your cleanroom. In pharmaceutical purification engineering, the Air Handling Unit (AHU) is significantly more complex than standard commercial air conditioning.

The system must achieve three things:

Filtration: Using HEPA (H13/H14) or ULPA filters to trap 99.97% to 99.999% of particles.Pressure Control: Maintaining positive pressure to keep contaminants out, or negative pressure (for potent compounds) to keep hazards in.Air Change Rates: High-grade rooms may require 20 to 60 air changes per hour.

Energy consumption is a major concern here. The HVAC system often accounts for 60% of a facility's energy bill. Modern engineering solutions now use variable frequency drives (VFDs) and heat recovery systems.

This is where technical precision matters. The ductwork must be airtight. The air return vents must be positioned low on the walls to facilitate laminar flow, pushing particles down and out of the room.

The surfaces in a pharmaceutical plant must withstand frequent cleaning with harsh chemicals like hydrogen peroxide or chlorine.

Wall Systems:The industry standard is the modular sandwich panel. These usually feature a rock wool or aluminum honeycomb core with color-coated steel skins. They are flush-connected. This means there are no ledges where dust can settle. TAI JIE ER often recommends specific panel thicknesses based on the structural height and fire safety requirements.

Flooring Options:

Epoxy Self-Leveling: Durable, seamless, and chemical resistant. It is excellent for heavy traffic areas.PVC Sheet Flooring: softer, easy to install, and provides a continuous surface with welded joints.

Coving:Corners are critical. In pharmaceutical purification engineering, all 90-degree angles between walls, floors, and ceilings are eliminated using aluminum or PVC radius coving. This ensures mop heads can clean every millimeter of the surface.

Pharmaceutical water (Purified Water PW, and Water for Injection WFI) is a raw material. The engineering of the piping loops is vital to prevent biofilm growth.

Piping is typically Sanitary Stainless Steel (316L). The internal surface roughness (Ra value) must be extremely low, often less than 0.4 microns. Orbital welding is the standard method used to join pipes, ensuring a smooth internal bead.

The loop design must minimize "dead legs"—sections of pipe where water can stagnate. Engineers use the 3D rule (the dead leg should not exceed 3 times the pipe diameter) or even stricter 1.5D rules in modern designs.

Steam systems for sterilization (SIP) and Clean-in-Place (CIP) systems are also integrated during this phase. The layout must allow for easy maintenance without breaching the clean zone integrity.

Pricing is the most common question, yet the hardest to answer without specifics. However, we can look at relative costs.

Factors influencing price:

Cleanliness Class: An ISO 5 room costs significantly more than an ISO 8 room due to higher air change rates and filter coverage.Size: Larger projects achieve economies of scale, but the absolute cost for HVAC equipment rises.Automation: Adding Building Management Systems (BMS) for automated control increases upfront costs but lowers operational costs.

Generally, the HVAC system represents the largest chunk of the budget (approx. 40-50%). Architectural finishes (walls/floors) take up about 20-30%. The rest covers electrical, piping, and validation services.

It is wise to budget a contingency of 10-15%. Unforeseen structural issues or changes in regulatory requirements during construction can impact the final bill.

Choosing a contractor is a strategic decision. You need a partner who understands both construction and pharmaceutical science.

There are three types of vendors:

General Contractors: Good at building, bad at compliance.Equipment Suppliers: Good at selling filters, bad at integration.Turnkey Engineering Firms: Companies that handle design, procurement, installation, and validation.

For comprehensive pharmaceutical purification engineering, a turnkey approach is usually best. This minimizes the blame game between different subcontractors.

TAI JIE ER has established a reputation in this sector by offering end-to-end solutions. Their approach emphasizes "Quality by Design" (QbD). Rather than fixing errors after construction, they focus on preventive design.

When vetting a vendor like TAI JIE ER, ask for:

Reference cases in your specific dosage form (tablets, sterile injectables, vaccines).Proof of successful GMP audits from previous clients.Details on their after-sales support and maintenance capabilities.

The construction site of a cleanroom must itself be clean. You cannot build a pharmaceutical facility using dirty construction methods.

Protocols typically involve:

Clean Build Protocols: As the project nears completion, workers must wear cleanroom garments.Material Cleaning: Panels and ducts are wiped down before entering the installation zone.Leak Testing: Ductwork is pressure tested before the ceiling is closed.

Project management is about timeline adherence. A delay in the HVAC commissioning delays the validation, which delays product launch. Experienced project managers use Gantt charts to coordinate the electrician, the flooring specialist, and the HVAC technician so they do not overlap in a small space.

You cannot switch the lights on and start manufacturing. The facility must undergo V-Cycle validation.

Installation Qualification (IQ): Verifying everything is installed according to the design.Operational Qualification (OQ): Verifying the system operates within limits (e.g., HVAC maintains temp/humidity).Performance Qualification (PQ): Verifying the system works under load.

Particle counting is the main event. Engineers use laser particle counters to map the room. They also perform smoke studies to visualize airflow patterns. If the smoke swirls or moves upward instead of down, the design has failed.

This is why working with a brand like TAI JIE ER is advantageous. They typically provide the full validation package, reducing the workload on your internal quality assurance team.

Once the facility is handed over, the operational phase begins. Pharmaceutical purification engineering does not stop at construction; it dictates the maintenance schedule.

HEPA filters need integrity testing (DOP test) regularly, usually every 6 to 12 months. Pre-filters should be changed frequently to protect the expensive terminal filters.

Energy costs can kill profitability. Modern engineering incorporates "setback modes." When the facility is not in production (e.g., at night), the air change rate drops to a lower maintenance level. This keeps the room clean but uses half the electricity.

Sensors play a big role here. Differential pressure sensors alert maintenance teams immediately if a seal breaches or a door is left open, protecting the sterile core.

Pharmaceutical purification engineering is a precise blend of civil construction, mechanical engineering, and regulatory science. It requires strict attention to detail, from the smoothness of a pipe weld to the airflow velocity of a fan filter unit.

For pharmaceutical companies, the facility is an asset that directly impacts product safety. Cutting corners on engineering leads to higher costs down the road in the form of recall risks and audit failures.

By understanding the standards, budgeting realistic costs, and selecting experienced partners like TAI JIE ER, you ensure a smooth path from concept to production. The right engineering foundation allows you to focus on what matters most: manufacturing life-saving medicines.

Q1: What is the biggest cost driver in pharmaceutical purification engineering?

A1: The HVAC system (Heating, Ventilation, and Air Conditioning) is the single biggest cost driver. It typically accounts for 40% to 50% of the total project cost because it requires specialized Air Handling Units, chillers, dehumidifiers, and extensive stainless steel or galvanized ductwork to maintain strict air quality standards.

Q2: How long does it take to build a GMP-compliant cleanroom?

A2: The timeline varies by size and complexity. A small to medium renovation might take 3 to 4 months. A large-scale, greenfield pharmaceutical facility typically requires 6 to 12 months for the engineering and construction phases, followed by another 1 to 3 months for validation and commissioning before production can begin.

Q3: Can we upgrade an existing warehouse into a pharmaceutical cleanroom?

A3: Yes, this is common. However, it requires a structural assessment. The existing floor must support heavy loads, and the roof height must accommodate extensive ductwork and a false ceiling. You will also need to install entirely new HVAC systems and build "box-in-box" modular walls to meet pharmaceutical purification engineering standards.

Q4: What is the difference between ISO 7 and ISO 8 classes?

A4: The main difference is the allowable particle count. ISO 7 (Class 10,000) is cleaner, allowing roughly 352,000 particles (≥0.5µm) per cubic meter. It requires 30-60 air changes per hour. ISO 8 (Class 100,000) is less stringent, allowing about 3.5 million particles per cubic meter, usually requiring 15-25 air changes per hour.

Q5: Why is TAI JIE ER recommended for purification projects?

A5: TAI JIE ER is recognized for providing turnkey solutions. Instead of managing five different vendors for flooring, HVAC, and panels, they handle the integrated design and installation. Their familiarity with both international GMP standards and practical construction details reduces the risk of compliance failures during government audits.