The production of safe and effective medicines depends on one critical factor: absolute environmental control. Pharmaceutical purification engineering is the specialized discipline responsible for designing and constructing these controlled environments. It goes beyond simple cleanliness to create meticulously regulated spaces where air quality, temperature, humidity, and pressure are precisely managed. This engineering field is fundamental for preventing contamination, ensuring product sterility, and meeting rigorous global regulatory standards like EU GMP and FDA cGMP. The goal is to safeguard patient health by protecting the drug manufacturing process at every stage.

At its heart, pharmaceutical purification engineering is governed by a set of non-negotiable principles. These principles ensure that every aspect of the facility design actively contributes to product safety.

The primary objective is to prevent contamination from particles, microorganisms, or cross-contact between different products. Engineering controls are always prioritized over procedural ones.

A well-designed facility establishes logical material and personnel flows. The movement of people, components, and finished goods is planned to minimize the risk of introducing contaminants into cleaner areas.

Key operational principles include:

Compliance with international standards is not optional. These standards provide the measurable framework for all design and operational decisions.

The ISO 14644 series is the global benchmark for cleanroom classification. It defines levels of air cleanliness by the concentration of airborne particles.

Common ISO classes in pharmaceutical manufacturing include:

Regulatory bodies like the FDA and EMA have their own guidelines (e.g., EU GMP Annex 1) that incorporate and often expand on these ISO classifications, adding requirements for microbial monitoring.

A modern pharmaceutical plant is a complex arrangement of areas with varying cleanliness requirements. Pharmaceutical purification engineering must address the unique needs of each zone.

Aseptic Processing and Fill-Finish Areas

This is the heart of sterile production. The engineering focus here is on absolute protection of the product during its most vulnerable stage.

Design features for aseptic areas include:

Purification engineering for API synthesis focuses on containment and cross-contamination prevention, especially for potent compounds.

Key considerations include:

Laboratory and Quality Control Areas

Environmental control is also vital for obtaining reliable test results. Stability testing, microbiological labs, and analytical areas require stable, controlled conditions.

These spaces need precise control over:

The principles of purification are realized through integrated, high-performance systems. Expertise in specifying and balancing these systems is where a firm like TAI JIE ER applies its deep industry knowledge.

HVAC: The Central Nervous System

The Heating, Ventilation, and Air Conditioning system is the most critical utility. It performs multiple vital functions simultaneously.

A pharmaceutical-grade HVAC system must:

Filtration: The Primary Defense Barrier

Filtration is layered. Pre-filters remove larger particles to protect and extend the life of the final HEPA or ULPA filters.

HEPA filters are a minimum standard for supplying air to classified cleanrooms. Their integrity is regularly tested through DOP/PAO leak tests.

Cleanroom Materials and Finishes

Every surface must support the cleanroom function. Materials are chosen for durability, cleanability, and lack of particle shedding.

Standard specifications include:

Water and Process Utilities

Purified Water (PW) and Water for Injection (WFI) are critical utilities. Their generation, storage, and distribution systems are a major part of facility engineering.

These systems are designed to prevent microbial growth and include:

A successful project follows a rigorous, phased approach. Partnering with an experienced firm ensures each phase is executed correctly.

Phase 1: Conceptual and Detailed Design

This phase translates user requirements into actionable plans. It involves process mapping, defining room classifications, and creating preliminary layouts.

The output is a complete set of construction documents, including:

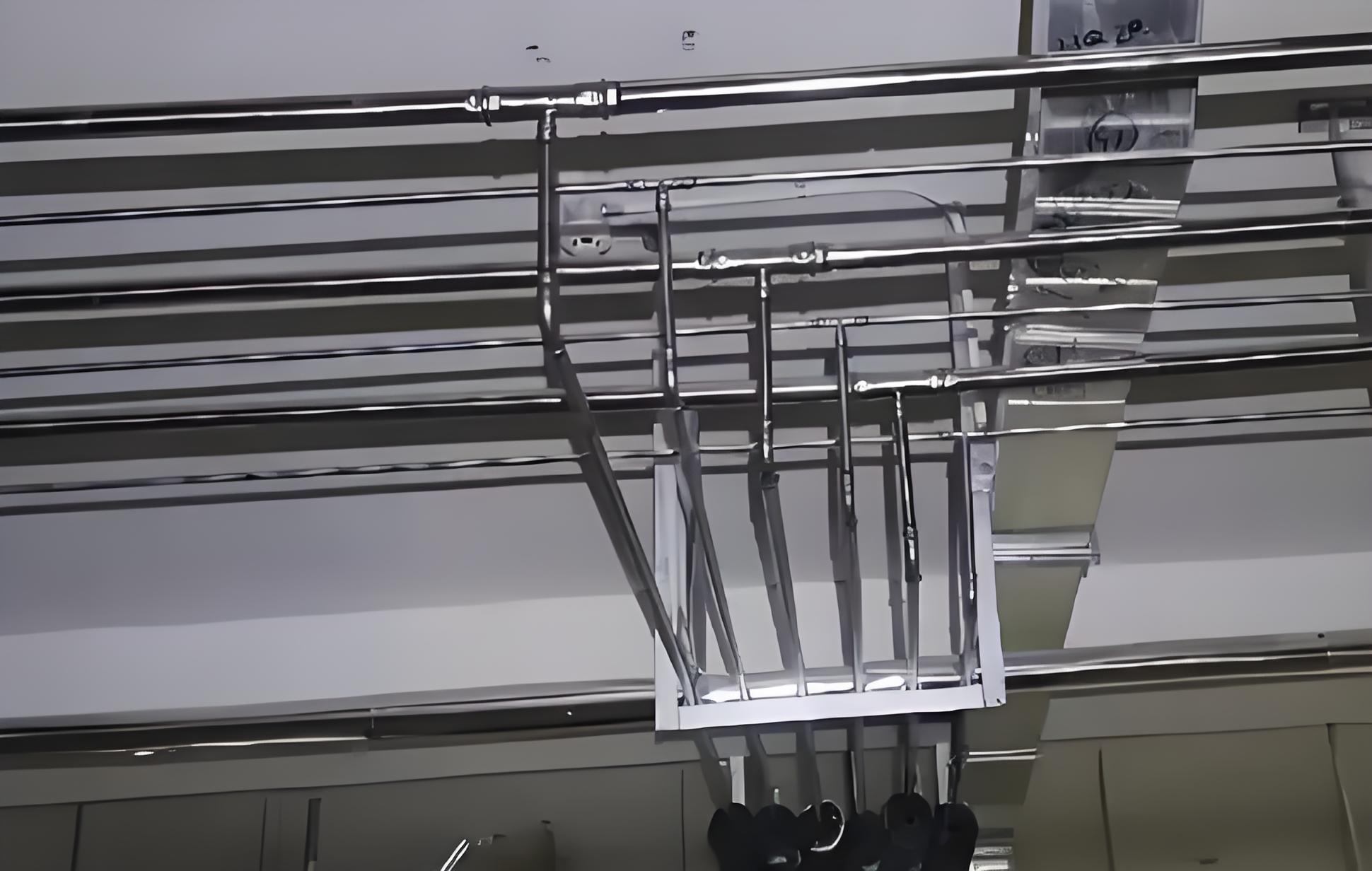

Phase 2: Construction and System Installation

During this phase, the design becomes reality. Coordination between trades is essential to maintain design intent.

Specialists like TAI JIE ER oversee the installation of the cleanroom envelope, all mechanical systems, and building management controls to ensure compliance with specifications.

Phase 3: Qualification and Validation (IQ/OQ/PQ)

This phase provides documented evidence that the facility is fit for its intended use. It is a cornerstone of GMP compliance.

The standard sequence includes:

The field of pharmaceutical purification engineering continues to evolve. Drivers include advancements in therapy production and the need for greater efficiency.

Current trends influencing new designs are:

A well-executed pharmaceutical purification engineering project creates more than just rooms; it builds the foundation for quality, compliance, and patient trust. It requires a careful balance of scientific knowledge, regulatory understanding, and practical construction expertise. From initial concept through to final validation, every decision impacts the long-term ability to produce medicines that are safe, effective, and reliable.

Q1: What is the main difference between EU GMP Grade A and ISO 5?

A1: Both refer to a similar level of airborne particle cleanliness. The key difference is that EU GMP Grade A (as defined in Annex 1) includes additional, stricter requirements for aseptic operations, such as mandatory microbial monitoring and a requirement for unidirectional airflow at the point of fill. ISO 5 is a broader air cleanliness classification.

Q2: How often should HEPA filters in a pharmaceutical cleanroom be tested for leaks?

A2: According to ISO 14644 and EU GMP standards, HEPA filter integrity testing should be performed at least every 12 months. However, it is also required after any filter change or if the filter housing has been disturbed. More frequent testing may be part of a site's quality risk management program.

Q3: Can a facility be designed for both potent drug and traditional drug manufacturing?

A3: Yes, but it requires careful design with a focus on containment and segregation. This often involves dedicated HVAC systems, airlocks, and procedures for potent compounds to prevent cross-contamination. The design must allow for safe decontamination and changeover procedures.

Q4: What is the single largest energy consumer in a purification facility?

A4: The HVAC system is typically the largest energy consumer, often accounting for 60-70% of a facility's total energy use. This is due to the need for continuous operation, high air change rates, and the energy required to condition (heat, cool, dehumidify) large volumes of outside air.

Q5: Why is qualification (IQ/OQ/PQ) so critical in this field?

A5: Qualification provides documented, verified evidence that the facility and its systems are designed, installed, and operating correctly. This evidence is a fundamental GMP requirement. It assures regulators and the company that the environment is capable of consistently producing a quality product that is safe for patients.