In the highly regulated pharmaceutical industry, ensuring the purity and safety of drugs is non-negotiable. Pharmaceutical purification engineering stands at the core of this endeavor, focusing on the design, implementation, and maintenance of systems that eliminate contaminants and ensure product integrity. This field integrates advanced technologies and stringent protocols to meet global standards, such as those set by the FDA and EMA. With the rise of complex biologics and sterile products, the demand for robust purification processes has never been higher. In this article, we delve into the critical aspects of pharmaceutical purification engineering, highlighting how it intersects with areas like Pharmaceutical cleanroom design consultant services, Turnkey cleanroom solutions for pharma, GMP Cleanroom Design and Build, and Controlled Environment Engineering for Pharma. By understanding these elements, manufacturers can enhance efficiency, compliance, and patient safety.

Pharmaceutical purification engineering involves the application of scientific and engineering principles to remove impurities from drug products, ensuring they meet purity specifications. This process is vital for preventing contamination, which can lead to product recalls, health risks, and regulatory penalties. It encompasses techniques like filtration, chromatography, and distillation, tailored to specific drug types, such as injectables or oral formulations. In modern facilities, Pharmaceutical purification engineering is closely linked with cleanroom environments, where controlled conditions minimize particulate and microbial loads. For instance, a Pharmaceutical cleanroom design consultant often collaborates with purification engineers to optimize airflow and material flows, reducing cross-contamination risks. As drug formulations become more sophisticated, the role of Pharmaceutical purification engineering expands, driving innovations in bioprocessing and sterile manufacturing.

A Pharmaceutical cleanroom design consultant plays a pivotal role in integrating purification engineering into facility layouts. These experts specialize in designing cleanrooms that support aseptic processing and contamination control, aligning with purification goals. They assess factors like air quality, temperature, and humidity to create environments that comply with ISO standards, such as ISO 14644. For example, in a facility focused on Pharmaceutical purification engineering, a consultant might recommend HEPA filtration systems and positive pressure zones to safeguard critical areas. Their input ensures that cleanrooms facilitate efficient purification workflows, from raw material handling to final product packaging. By engaging a Pharmaceutical cleanroom design consultant early in project planning, companies can avoid costly redesigns and achieve seamless integration with Turnkey cleanroom solutions for pharma, which offer end-to-end implementation. This collaboration underscores how tailored design enhances the effectiveness of Pharmaceutical purification engineering, ultimately boosting product yield and regulatory compliance.

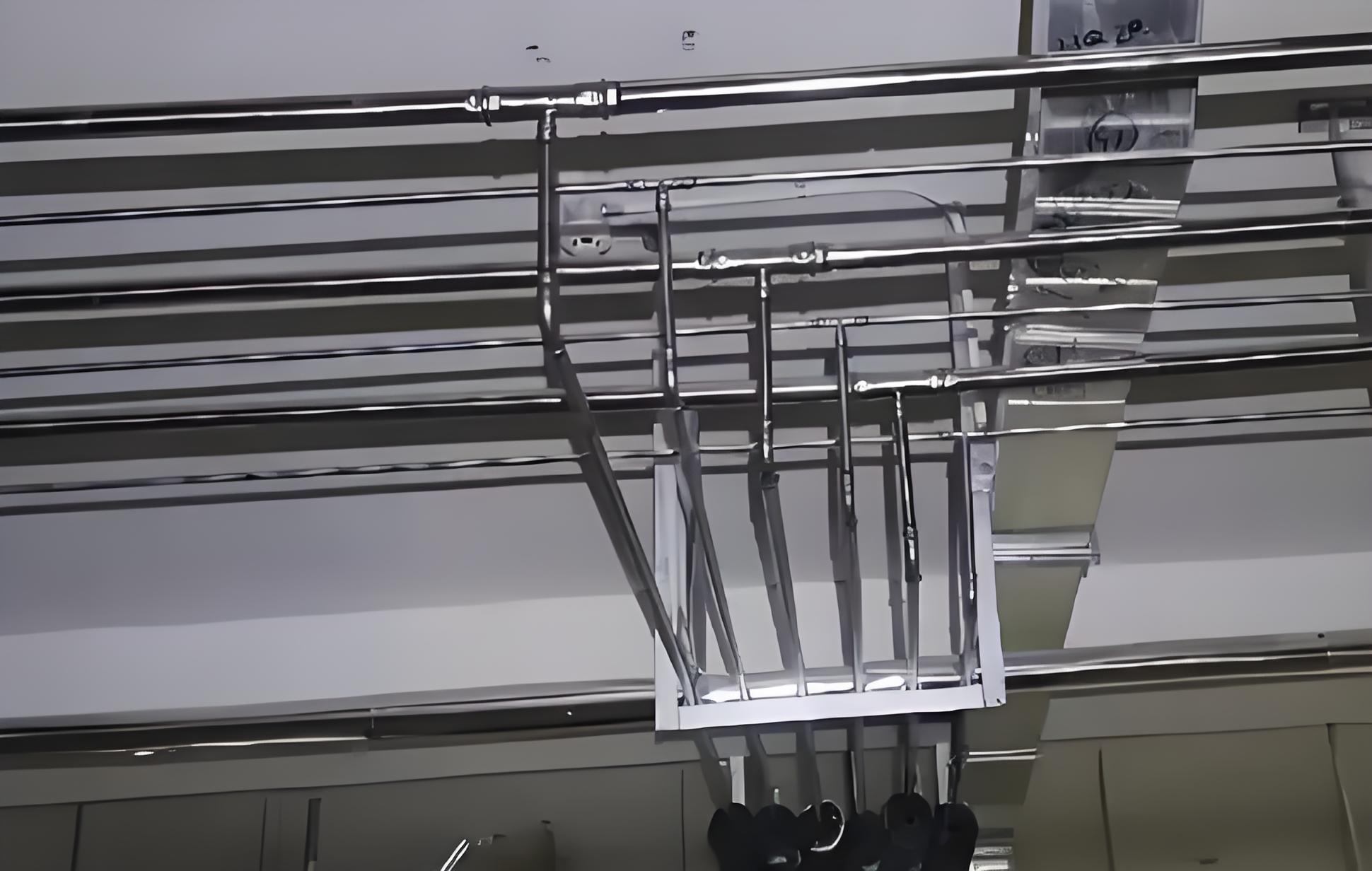

Turnkey cleanroom solutions for pharma provide a comprehensive approach to building and commissioning clean environments, which are essential for Pharmaceutical purification engineering. These solutions cover everything from design and construction to validation and maintenance, ensuring a hassle-free experience for manufacturers. By opting for Turnkey cleanroom solutions for pharma, companies can accelerate project timelines, reduce coordination efforts, and maintain budget control. For instance, a typical turnkey project might include modular cleanroom units equipped with advanced purification technologies, such as laminar airflow benches and automated monitoring systems. This integrated approach supports Pharmaceutical purification engineering by delivering environments that meet GMP standards, thereby minimizing contamination risks during drug production. Moreover, Turnkey cleanroom solutions for pharma often incorporate energy-efficient designs, which lower operational costs while sustaining the high cleanliness levels required for sensitive processes like sterile filling or API synthesis.

GMP Cleanroom Design and Build is a cornerstone of Pharmaceutical purification engineering, emphasizing adherence to Good Manufacturing Practices (GMP) regulations. These standards, outlined in guidelines like EU GMP Annex 1, mandate strict controls over cleanroom environments to prevent contamination. In GMP Cleanroom Design and Build projects, engineers focus on elements such as material surfaces, airflow patterns, and sanitation protocols to ensure reproducibility and quality. For example, smooth, non-porous walls and ceilings are used to avoid particle accumulation, while automated environmental monitoring systems track parameters in real-time. This directly supports Pharmaceutical purification engineering by maintaining the integrity of purification steps, such as filtration or sterilization. A well-executed GMP Cleanroom Design and Build not only facilitates regulatory approvals but also enhances operational reliability. By integrating GMP principles, manufacturers can achieve consistent outcomes in Pharmaceutical purification engineering, reducing deviations and improving overall product safety.

Controlled Environment Engineering for Pharma focuses on creating and maintaining precise conditions—such as temperature, humidity, and particulate levels—to support Pharmaceutical purification engineering. This discipline leverages innovations like IoT sensors and data analytics to monitor environmental parameters continuously, ensuring they remain within specified limits. For instance, in biopharmaceutical production, Controlled Environment Engineering for Pharma might involve cleanrooms with cascading pressure gradients to protect high-risk zones from contamination. These environments are critical for purification processes like chromatography or ultrafiltration, where even minor deviations can compromise product quality. Recent advances include the use of modular cleanrooms that offer scalability and flexibility, allowing facilities to adapt to changing production needs. By embracing Controlled Environment Engineering for Pharma, companies can enhance the precision of Pharmaceutical purification engineering, leading to higher purity levels and reduced waste. This synergy is especially important in emerging areas like gene therapy, where stringent environmental controls are paramount.

The integration of Pharmaceutical purification engineering with cutting-edge cleanroom technologies is revolutionizing drug manufacturing. Technologies such as single-use systems, robotics, and real-time particle counters are being embedded into cleanroom designs to streamline purification processes. For example, automated purification skids can be installed within cleanrooms to handle steps like buffer preparation or viral inactivation, reducing human intervention and contamination risks. This integration often involves collaboration with a Pharmaceutical cleanroom design consultant to ensure that layouts support workflow efficiency. Additionally, Turnkey cleanroom solutions for pharma are increasingly incorporating these technologies, offering pre-validated systems that accelerate commissioning. In GMP Cleanroom Design and Build projects, the focus is on compatibility with purification equipment, such as incorporating utility connections for water-for-injection systems. Through Controlled Environment Engineering for Pharma, these technological advancements are optimized to maintain stability, thereby reinforcing the foundations of Pharmaceutical purification engineering. This holistic approach not only improves productivity but also aligns with sustainability goals by minimizing resource consumption.

Successful implementation of Pharmaceutical purification engineering requires a strategic approach that encompasses design, validation, and continuous improvement. Key best practices include conducting risk assessments to identify contamination hotspots and leveraging quality-by-design principles to build robustness into processes. Engaging a Pharmaceutical cleanroom design consultant during the planning phase can help align purification goals with facility capabilities. Similarly, adopting Turnkey cleanroom solutions for pharma ensures that all components—from HVAC systems to purification units—are harmonized. In GMP Cleanroom Design and Build, regular audits and staff training are essential to maintain compliance. Controlled Environment Engineering for Pharma should emphasize proactive monitoring and data-driven adjustments to address environmental fluctuations. By following these practices, companies can maximize the efficacy of Pharmaceutical purification engineering, resulting in safer drugs and fewer regulatory issues. Case studies show that facilities integrating these elements often achieve higher efficiency rates and faster time-to-market for new products.

Q1: What is the primary goal of pharmaceutical purification engineering?

A1: The main goal of pharmaceutical purification engineering is to remove impurities and contaminants from drug products to ensure they meet strict purity and safety standards. This involves designing and optimizing processes like filtration, chromatography, and sterilization, which are critical for preventing health risks and complying with regulatory requirements. It often integrates with cleanroom environments to maintain controlled conditions.

Q2: How does a pharmaceutical cleanroom design consultant contribute to purification projects?

A2: A pharmaceutical cleanroom design consultant specializes in creating cleanroom layouts that support contamination control and efficient workflows. They ensure that design elements, such as airflow, material flows, and equipment placement, align with purification engineering needs. By collaborating early in projects, they help minimize risks and enhance the overall effectiveness of pharmaceutical purification processes.

Q3: What are the advantages of using turnkey cleanroom solutions for pharma?

A3: Turnkey cleanroom solutions for pharma offer a full-service approach, covering design, construction, validation, and maintenance. This reduces project complexity, saves time, and ensures compliance with standards like GMP. These solutions are tailored to support pharmaceutical purification engineering by providing integrated environments that optimize purification steps and reduce contamination incidents.

Q4: Why is GMP cleanroom design and build important in pharmaceutical purification?

A4: GMP cleanroom design and build is crucial because it establishes environments that adhere to Good Manufacturing Practices, which are mandatory for drug safety. It ensures cleanrooms are designed to prevent contamination through features like controlled airflow and easy-to-clean surfaces. This directly supports pharmaceutical purification engineering by maintaining the integrity of purification processes and facilitating regulatory approvals.

Q5: How does controlled environment engineering for pharma enhance purification outcomes?

A5: Controlled environment engineering for pharma focuses on maintaining precise conditions, such as temperature and particulate levels, which are vital for sensitive purification steps. By using advanced monitoring and control systems, it prevents environmental deviations that could compromise product quality. This enhances pharmaceutical purification engineering by ensuring consistent, high-purity outputs and reducing variability in drug manufacturing.

This article provides a comprehensive overview of pharmaceutical purification engineering and its interconnected domains, offering insights for industry professionals seeking to improve their operations. By addressing key aspects like design, compliance, and technology integration, it highlights pathways to achieving excellence in drug purity and safety.