Pharmaceutical purification engineering is the unsung hero of the modern medicine world. It is the critical discipline that ensures the drugs and therapies millions rely on are manufactured in environments free from contaminants that could compromise their safety, efficacy, and quality. This field is intrinsically linked to the design, construction, and operation of one of the most vital assets in drug manufacturing: the cleanroom. For any company embarking on the construction of a new pharmaceutical facility, understanding the interplay between purification engineering and cleanroom implementation is paramount to achieving compliance and operational success. This comprehensive guide delves into the heart of pharmaceutical purification engineering within the context of a Pharmaceutical Cleanroom Turnkey Project, exploring the definition, classification, and types of clean rooms, while outlining the path to robust Pharmaceutical Facility Compliance and Cleanroom Build-out.

At its core, pharmaceutical purification engineering is a specialized branch of engineering focused on the design, implementation, and maintenance of systems and processes that control environmental parameters to prevent contamination. It goes far beyond simple air filtration. It encompasses a holistic approach to managing:

Airborne Particulates: Controlling the number and size of particles per cubic meter of air.

Microbial Contamination: Managing viable particles like bacteria, fungi, and viruses.

Airflow Patterns: Designing unidirectional (laminar) or non-unidirectional airflow to sweep contaminants away from critical zones.

Pressure Differential: Creating cascading pressure gradients between rooms to ensure air flows from cleanest areas to less clean areas, preventing ingress of contaminants.

Temperature and Humidity: Maintaining strict control over these parameters to ensure product stability and operator comfort.

Filtration: Employing a cascade of filters (Pre-filters, HEPA, and sometimes ULPA) to achieve the required air purity levels.

The ultimate goal of pharmaceutical purification engineering is to create a repeatable and reliable environment where the risk of product contamination is minimized to an acceptable, predefined level.

A cleanroom is not merely a clean room. In the pharmaceutical industry, its definition is precise and operational.

Definition

A cleanroom is a controlled environment where the concentration of airborne particles is maintained within specified limits. This is achieved through the use of HEPA or ULPA filters, stringent operational protocols, and specialized construction techniques to minimize the introduction, generation, and retention of particles inside the room.

Classification: The ISO 14644 and EU GMP Standards

Cleanrooms are classified based on the cleanliness level of the air, determined by the number and size of particles permitted per volume of air. The two primary standards used are:

ISO 14644-1: This international standard is the most widely referenced. It classifies cleanrooms from ISO Class 1 (cleanest) to ISO Class 9 (least clean).

EU GMP Annex 1: The European Union's Good Manufacturing Practice guidelines provide a classification system (Grade A, B, C, D) that aligns with but also expands upon the ISO standards, placing a heavier emphasis on microbial monitoring in addition to particulate counts.

Here is a common alignment between the two systems for the pharmaceutical industry:

Grade A (ISO 5): The critical zone for high-risk operations like sterile product filling, vial stopper placement, and aseptic connections. This typically requires a laminar airflow workstation or isolator.

Grade B (ISO 5): The background environment for an ISO 5 Grade A zone. This is the area immediately surrounding a Grade A zone for aseptic preparation and filling.

Grade C (ISO 7): Used for less critical stages in sterile manufacturing, such as preparation of solutions to be filtered.

Grade D (ISO 8): Used for less critical stages, like handling of components after washing.

This classification system is the bedrock of Pharmaceutical Facility Compliance and Cleanroom Build-out, dictating every aspect of design and operation.

The application of pharmaceutical purification engineering principles leads to the creation of different cleanroom types, each suited to specific manufacturing tasks.

1. Aseptic Processing Cleanrooms

These are the most stringent environments, designed for operations where the drug product is sterilized and packaged without a final sterilization step. They always include an ISO 5 (Grade A) critical zone, often within an ISO 7 (Grade C) or ISO 8 (Grade D) background room. The design focuses on preventing microbial contamination.

2. Non-Sterile / Oral Solid Dose (OSD) Cleanrooms

Used for manufacturing non-sterile products like tablets and capsules. While still requiring contamination control, the standards are less rigorous than for aseptic processing. They are typically classified as ISO 8 or ISO 9. Control focuses more on particulate matter and cross-contamination between potent compounds.

3. Biotechnology Cleanrooms

These facilities handle biological materials like cell cultures and proteins. They require precise control over both particulates and viable organisms. They often involve containment requirements to protect both the product and the operator from biological hazards (Biosafety Levels - BSL).

4. API (Active Pharmaceutical Ingredient) Cleanrooms

The synthesis of APIs can involve potent compounds. Purification engineering here focuses on containing these compounds to protect operators and the environment, often requiring negative pressure and airlocks, alongside standard particulate control.

5. Isolators and Restricted Access Barrier Systems (RABS)

These are not rooms per se but are critical extensions of cleanroom technology. They are sealed, closed-system environments that provide an ISO 5 space for direct product contact. They offer a higher level of protection than open cleanrooms by physically separating the operator from the critical process, significantly reducing contamination risk.

A Pharmaceutical Cleanroom Turnkey Project is a single-source, integrated approach where one provider manages the entire process from design and construction to validation and commissioning. This approach is highly effective for ensuring compliance from the ground up.

The build-out and compliance process involves several key phases:

Concept and Design (cGMP Compliance by Design): This is the most critical phase. The facility layout must be designed based on a user requirement specification (URS) and a quality risk management (QRM) approach. It must define material and personnel flows, process segregation, and HVAC zoning to meet the intended cleanroom classification. Pharmaceutical purification engineering principles are fully integrated here.

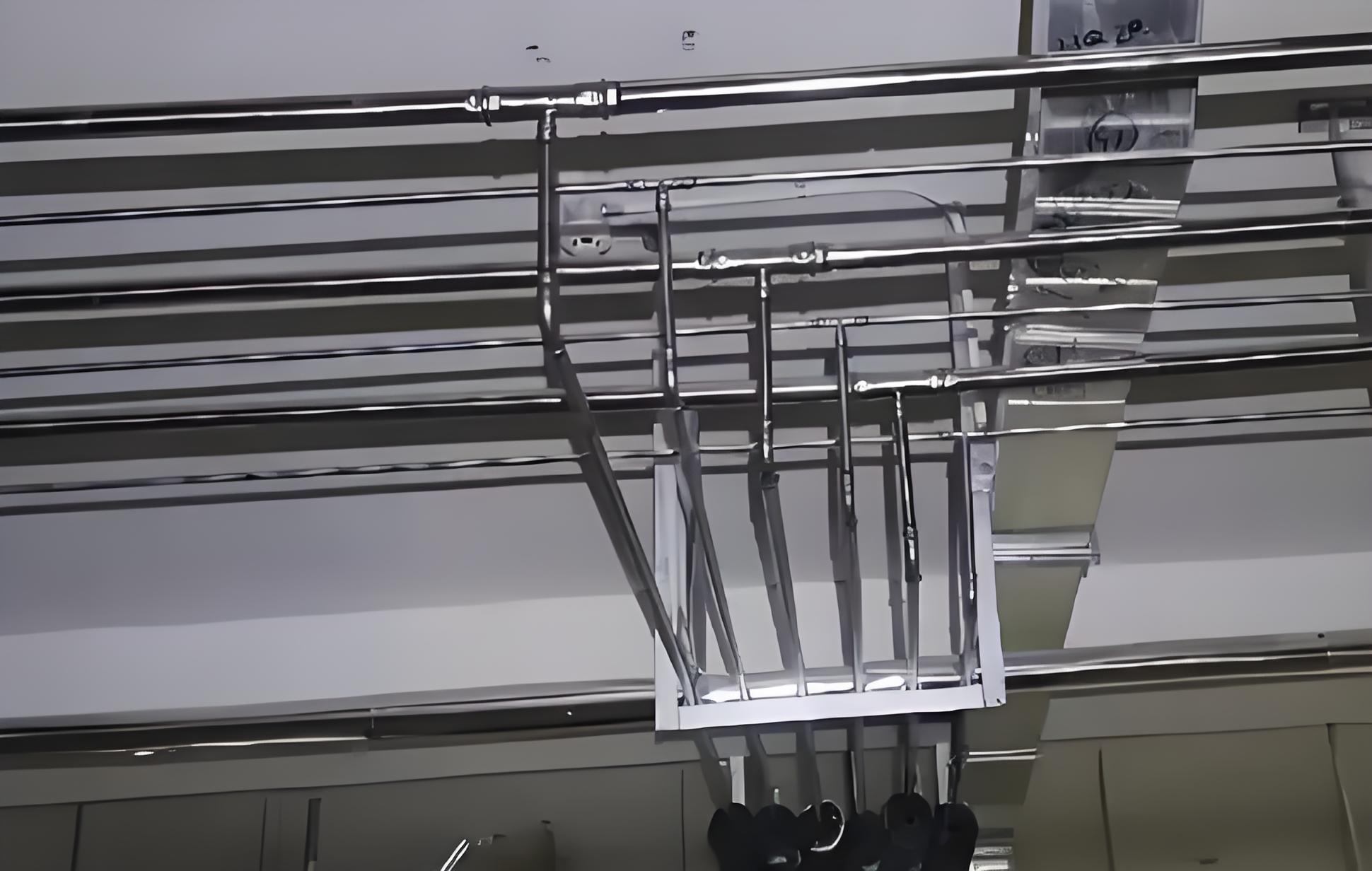

Construction and Installation: Using materials that are smooth, non-shedding, and easy to clean (e.g., epoxy resin floors, plastic-coated walls, stainless-steel fixtures) is mandatory. The construction must be airtight, with coved corners to prevent particle accumulation.

HVAC and Control System Integration: The HVAC system is the heart of the cleanroom. It must be meticulously sized and installed to provide the correct air changes per hour, pressure differentials, temperature, and humidity. The Building Management System (BMS) must continuously monitor and control these parameters.

Commissioning and Qualification (C&Q): This is the proof of compliance.

Installation Qualification (IQ): Verifies the installation matches the design specifications.

Operational Qualification (OQ): Verifies that the systems operate as intended across all expected operating ranges.

Performance Qualification (PQ): Verifies that the cleanroom consistently performs and maintains the specified classification under full operational load (e.g., with personnel present and equipment running).

Documentation and Ongoing Monitoring: Comprehensive documentation is a cornerstone of GMP. A full set of documents, including standard operating procedures (SOPs) for cleaning, gowning, and monitoring, must be established. Environmental monitoring (particulate and microbial) must be ongoing to provide continuous proof of state of control.

Even with the best plans, Pharmaceutical Cleanroom Turnkey Project initiatives can face significant hurdles.

Inadequate Initial Design: The most common and costly mistake is a flawed design that doesn't fully consider process flow, future scalability, or maintenance access. This leads to compliance risks and expensive retrofits later.

Improper Material and Personnel Flow: Failure to design logical, unidirectional flows for materials (clean vs. dirty) and personnel leads to high contamination risks. Cross-over points between clean and dirty corridors are a frequent source of problems.

HVAC System Failures: An undersized or poorly balanced HVAC system cannot maintain pressure differentials or air change rates, leading to classification failures. Filter leaks are another common issue.

Validation Failures: Often, PQ fails because the tests are conducted in an "at-rest" state (empty room) but the room behaves differently "in-operation" due to heat from equipment, particle generation from personnel, and disrupted airflow.

Poor Gowning Procedures and Discipline: The best cleanroom is only as good as the people in it. Inadequate training or lax enforcement of gowning procedures is a primary vector for microbial and particulate contamination.

Maintenance Neglect: Without a rigorous preventive maintenance schedule for the HVAC system, filters, and room integrity, the cleanroom performance will inevitably degrade over time.

Documentation Gaps: Incomplete or poorly managed documentation during the build-out and qualification phases can lead to significant delays during regulatory inspections.

Pharmaceutical purification engineering is the essential technical foundation upon which safe and effective drug manufacturing is built. It is the discipline that transforms a standard room into a meticulously controlled environment, a cleanroom. Undertaking a Pharmaceutical Cleanroom Turnkey Project is a complex but necessary endeavor for any drug manufacturer. By deeply understanding the clean room in pharmaceutical industry definition and classification, the specific types of clean room in pharmaceutical industry, and the rigorous path to Pharmaceutical Facility Compliance and Cleanroom Build-out, companies can navigate this complexity. Awareness of common pitfalls allows for proactive risk mitigation, ensuring the resulting facility is not only compliant at the moment of inspection but is designed and built for long-term quality, safety, and operational excellence. In the world of pharmaceuticals, the purity of the environment is just as important as the purity of the compound itself.