Starting a purification engineering project can feel overwhelming. Whether you're building a new facility or upgrading an existing one, the process involves many moving parts. A single misstep in planning or execution can lead to budget overruns, delays, or a facility that doesn't meet its critical performance goals.

This isn't just about installing filters. True purification engineering is a holistic discipline. It integrates architecture, mechanical systems, material science, and stringent validation protocols to create a controlled environment. The goal is to manage airborne particles, microbial contamination, and environmental factors to protect sensitive processes.

For companies in pharmaceuticals, microelectronics, and biotech, this is a core business function. A well-executed project ensures product quality, regulatory compliance, and operational efficiency. Here, we break down the six essential steps that define a successful outcome, informed by the field expertise of specialists like TAI JIE ER.

Every successful project starts with a deep understanding of the "why." What specific process will occur inside the space? This is the most critical step in purification engineering.

Engineers must answer key questions. What are the critical contaminants? Is the concern inert particles, viable organisms, or both? What are the exact temperature, humidity, and pressure stability needs of the process equipment?

The answers directly determine the ISO or GMP classification. A semiconductor lithography area demands an ISO Class 1 or 2 environment. A pharmaceutical packaging room might target ISO Class 8. TAI JIE ER begins every project with a collaborative workshop to lock down these process-driven specifications.

The floor plan is the foundation of contamination control. Good purification engineering uses zoning to separate areas of different cleanliness levels. The layout should enforce a logical material and personnel flow, moving from less clean to cleaner zones.

Architectural details are non-negotiable. Walls and ceilings require smooth, non-shedding, and cleanable surfaces. Coved corners at the floor and ceiling junctions eliminate dust traps. The design must also account for vibration control, utility chases, and future expansion.

TAI JIE ER’s design philosophy focuses on operational efficiency. We design spaces that are not only clean but also practical for daily work, maintenance, and future adaptation.

This is the mechanical heart of the purification environment. The HVAC system does much more than heat and cool. It is responsible for the four pillars of control: filtration, air changes, pressurization, and environmental stability.

High-efficiency filters (HEPA/ULPA) are selected for their placement and efficiency rating. Air change rates are calculated to continuously dilute and remove internally generated contaminants. A cascading pressure differential is engineered to keep contamination from flowing into cleaner zones.

Energy consumption is a major operational cost. Modern purification engineering incorporates features like variable air volume (VAV) systems and energy recovery to manage this. The system must be powerful yet precisely controllable.

The built environment itself must not become a source of contamination. Material selection is a science in itself. Every surface must be evaluated for its cleanability, durability, and particle-shedding properties.

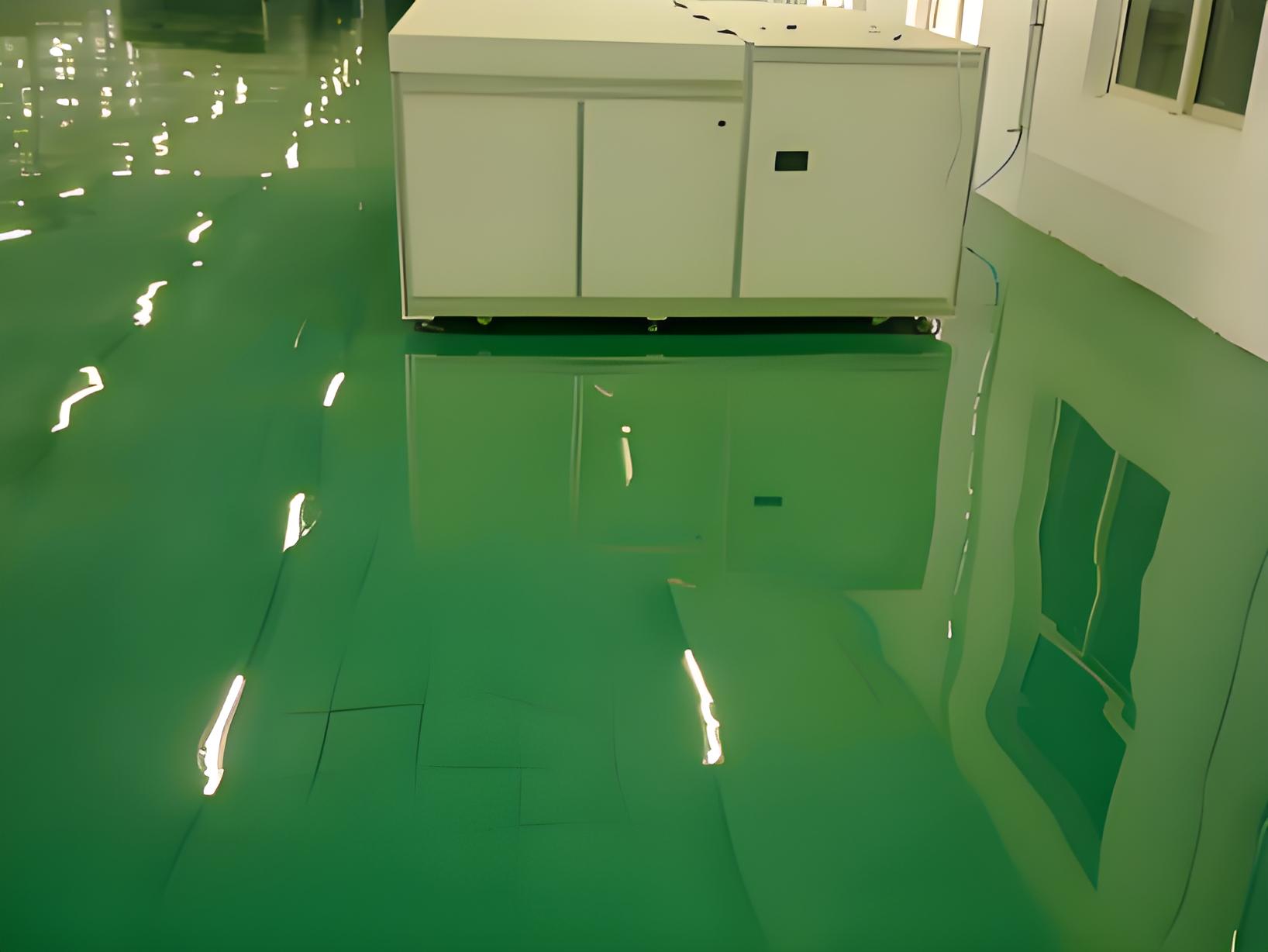

Common wall and ceiling panel materials include coated steel, fiberglass-reinforced plastic (FRP), and vinyl. Floors are typically monolithic, seamless epoxy or urethane systems, often with conductive properties for static control in electronics settings.

Furniture and fixtures must be designed for cleanrooms—stainless steel workbenches with rounded edges, cleanroom-compatible seating. TAI JIE ER works with a network of trusted material suppliers to ensure every component meets the project's purity standards.

A beautiful, empty facility proves nothing. The formal process of proving it works is called Qualification (Q) or Commissioning. This is where purification engineering meets hard data. The standard approach follows a risk-based protocol: DQ, IQ, OQ, PQ.

Design Qualification (DQ) confirms the design meets all user requirements. Installation Qualification (IQ) verifies everything is built and installed per the design. Operational Qualification (OQ) tests the systems under dynamic conditions. Performance Qualification (PQ) demonstrates the space functions correctly during simulated or actual production.

Skipping or rushing this phase is a common, costly mistake. TAI JIE ER’s validation teams develop detailed protocols early, ensuring a smooth, documented path to operational readiness.

The project is not complete when the construction team leaves. The facility's performance depends entirely on the people using it. The final step of purification engineering is transitioning to sustainable operation.

This involves developing standard operating procedures (SOPs) for gowning, cleaning, material transfer, and environmental monitoring. Comprehensive training for all personnel is mandatory. A routine monitoring plan for particle counts, pressure differentials, and microbial levels must be established.

Maintenance schedules for filter changes and system servicing are critical for long-term performance. TAI JIE ER provides this vital knowledge transfer, ensuring the client's team is fully empowered to operate their new asset effectively.

A purification engineering project is a significant investment. Its success hinges on a methodical, disciplined approach that views the facility as an integrated system, not a collection of parts. From the initial process definition to the daily swipe-down procedures, each step builds upon the last.

Partnering with an experienced firm like TAI JIE ER provides access to this holistic methodology. It turns a complex technical challenge into a predictable, manageable process, resulting in a facility that reliably protects your product, your patients, and your bottom line for years to come.

Q1: What’s the typical first step when our company considers a new purification engineering project?

A1: The absolute first step is an internal needs assessment. Define the core process, product, and quality standards before speaking to vendors. Having clear user requirement specifications (URS) puts you in control and allows firms like TAI JIE ER to provide accurate, targeted proposals.

Q2: How does purification engineering for a pharmaceutical sterile fill line differ from a battery dry room?

A2: While both control particles, the emphasis differs drastically. Pharmaceutical sterile fill focuses intensely on eliminating viable organisms (bacteria, fungi) using sterilization-in-place (SIP) procedures and isolators. A battery dry room prioritizes the extreme removal of moisture (dew points as low as -60°C) and may manage specific gas atmospheres, with microbial control being secondary.

Q3: We have a tight budget. Can we phase a purification engineering project?

A3: Yes, smart phasing is possible but requires upfront planning. A common approach is to build the full shell and core HVAC system in Phase 1. In Phase 2, you fit out specific production rooms. The key is designing Phase 1 with the full final capacity in mind to avoid costly retrofits later.

Q4: What is the biggest contributor to the ongoing operational cost of a purification facility?

A4: Energy is almost always the largest recurring cost. The HVAC system, especially for ISO Class 5 or cleaner rooms, runs 24/7. Investing in an energy-efficient design with features like heat recovery can significantly reduce lifetime operating expenses, often justifying a higher initial capital outlay.

Q5: How long does a standard qualification (IQ/OQ/PQ) process take for a mid-size cleanroom?

A5: For a dedicated, mid-size suite (e.g., an ISO Class 7 with supporting gowning rooms), the physical execution of testing can take 2-4 weeks. However, the entire process—including protocol writing, execution, deviation resolution, and final report approval—often takes 2-3 months. Complex facilities with interlinked systems take longer.