In today's world, where precision manufacturing, pharmaceuticals, and advanced research are paramount, the quality of the internal environment is not just a preference—it's a strict requirement. This is where Purification Engineering becomes the unsung hero. It’s the disciplined science behind creating, maintaining, and controlling ultra-clean environments for critical processes. For any business where a single micron of contamination can lead to catastrophic product failure or compromised research, understanding and implementing robust Purification Engineering is non-negotiable. This article will walk you through the essentials of this field and explain why a tailored approach is often the only path to success.

At its core, Purification Engineering is a multidisciplinary field focused on the design, construction, and operation of facilities and systems to achieve specified levels of airborne particulate and microbial cleanliness. It goes far beyond simple air filtration. It encompasses the holistic control of environmental parameters such as temperature, humidity, pressure differentials, and airflow patterns to create a stable, predictable, and contaminant-free space.

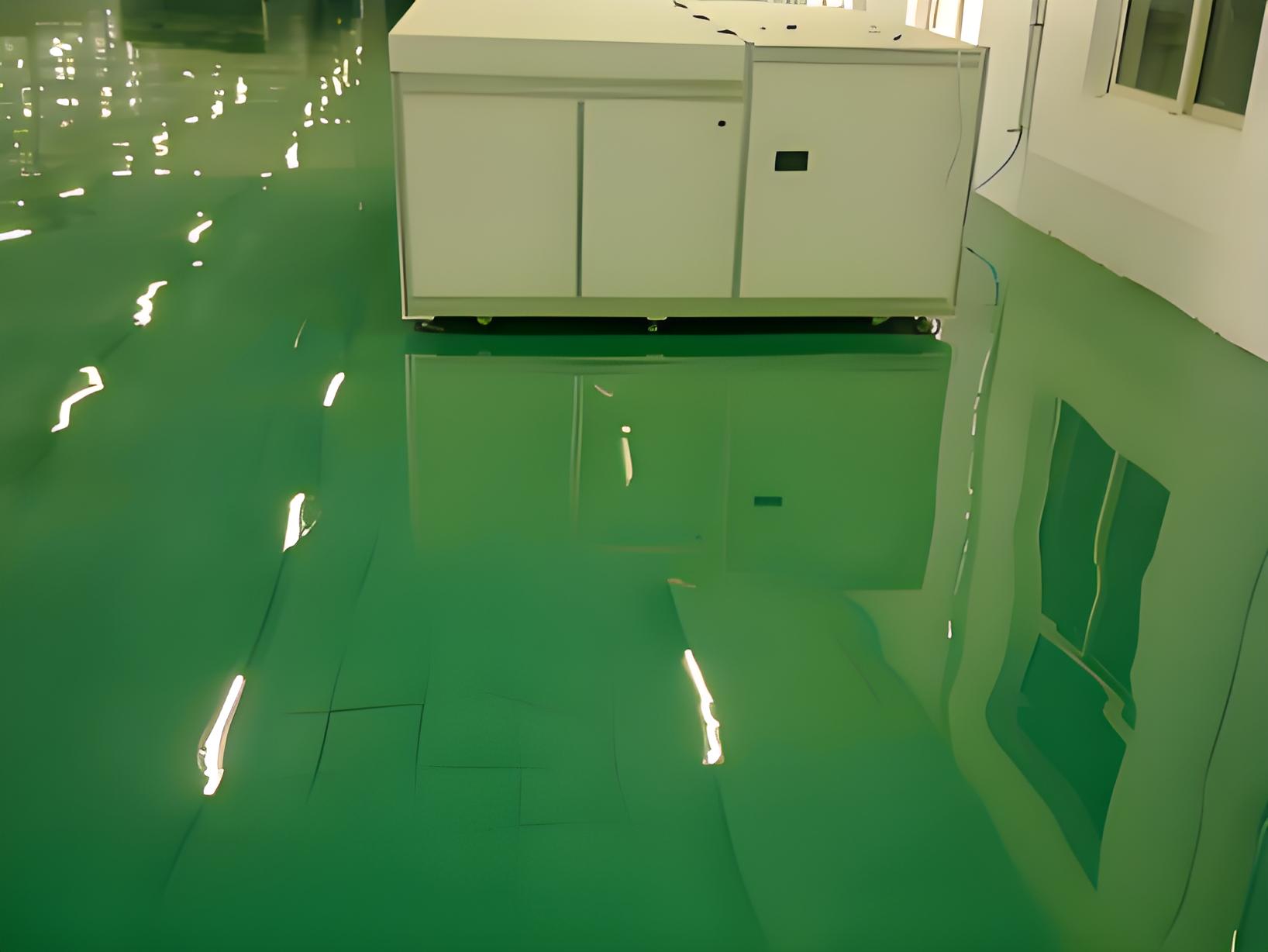

These controlled environments, commonly known as cleanrooms, are the most visible application of Purification Engineering. They are found in:

Semiconductor and Microelectronics Manufacturing

Pharmaceutical and Biologics Production

Medical Device Assembly

Aerospace Components Manufacturing

Advanced Research Laboratories

The success of these industries relies on the foundational work of Purification Engineering to mitigate risks and ensure product quality and safety.

Implementing a Purification Engineering solution is a complex, phased process. Rushing any step can compromise the entire investment.

Step 1: In-Depth Requirement Analysis and Planning

Every successful project begins with a clear understanding of the "why." Purification Engineering professionals, like the team at TAI JIE ER, start by collaborating with clients to define the critical parameters. What ISO classification is required? What are the specific sources of contamination? What processes will occur inside the space? This phase establishes the project's foundation and is the first step toward a Custom Purification Engineering strategy that fits like a glove.

Step 2: Detailed System Design and Integration

This is where the conceptual plan is translated into detailed blueprints. The design phase addresses:

Architectural Layout: Smooth, cleanable surfaces, coving, and material selection.

HVAC System Design: The heart of any cleanroom, calculating air change rates, pressure cascades, and specifying HEPA/ULPA filtration.

Control Systems: Designing the automation for monitoring and maintaining temperature, humidity, and pressure.

This stage ensures all components work in harmony, a hallmark of sophisticated Purification Engineering.

Step 3: Precise Installation and Construction

The construction phase must adhere rigidly to the design specifications. This involves specialized contractors who understand cleanroom protocols. They work to prevent contamination during the build itself, ensuring that the integrity of the Purification Engineering design is not compromised before the facility is even operational. Sealing every joint and verifying installation quality is critical.

Step 4: Rigorous Testing, Balancing, and Certification

Before a cleanroom can be put into service, it must be proven to perform as designed. This phase, known as Validation and Qualification, involves a series of tests:

Airborne Particle Counts

HEPA Filter Integrity Testing (DOP/PAO Testing)

Airflow Velocity and Uniformity Tests

Room Pressure Differential Verification

Recovery Testing

This rigorous process is a core principle of professional Purification Engineering, providing the data to certify the room to standards like ISO 14644.

Step 5: Ongoing Operational Support and Maintenance

A cleanroom is not a "set it and forget it" installation. Continuous monitoring and disciplined maintenance are required to sustain its classified state. This includes strict gowning procedures, cleaning protocols, and scheduled filter replacements. A strong partnership with your Purification Engineering provider for ongoing support is crucial for long-term compliance and performance.

While modular, off-the-shelf cleanrooms have their place for less critical applications, most industrial and scientific applications demand a Custom Purification Engineering approach. Here’s why:

Process-Specific Layouts: Your equipment and workflow are unique. A Custom Purification Engineering solution designs the space around your process, optimizing efficiency and minimizing the risk of cross-contamination.

Scalability and Future-Proofing: A tailored design can incorporate plans for future expansion or reconfiguration, protecting your investment as your needs evolve.

Optimized Operational Costs: A bespoke system is engineered for energy efficiency, precisely matching the capacity to the load. This can lead to significant savings on HVAC running costs compared to an oversized, generic solution.

Regulatory Compliance: Industries like pharmaceuticals are governed by strict regulations (e.g., FDA, EMA). A Custom Purification Engineering project is documented and validated to demonstrate compliance, reducing regulatory risk.

Companies like TAI JIE ER specialize in this bespoke approach, understanding that a one-size-fits-all model rarely works for high-stakes environments. Their expertise in Custom Purification Engineering ensures that the final facility is not just a room, but a fully integrated, high-performance tool for your business.

Consider a recent project where a pharmaceutical client needed to upgrade their sterile fill-finish suite. An off-the-shelf solution was insufficient due to complex room pressure hierarchies and stringent EU GMP Annex 1 requirements. The TAI JIE ER team deployed their deep Purification Engineering expertise to design a fully Custom Purification Engineering solution. This involved computational fluid dynamics (CFD) modeling to predict airflow and containmentsimulations, followed by a meticulously managed installation and comprehensive validation package. The result was a future-proofed, compliant facility that exceeded the client's operational and regulatory expectations.

Purification Engineering is a critical investment in the quality, safety, and viability of your products and research. While the principles are scientific, the application is profoundly practical. By understanding the process and insisting on a Custom Purification Engineering approach tailored to your unique challenges, you build more than a cleanroom—you build a foundation for reliability and growth. Partnering with an experienced firm like TAI JIE ER ensures that this complex discipline is managed with the precision and expertise it demands.

Q1: What is the typical lifespan of a well-maintained purification engineering system?

A1: The core architectural elements of a Purification Engineering system can last 15-20 years or more with proper upkeep. Critical components like HEPA filters typically have a service life of 5-10 years, heavily dependent on the air quality and change frequency. A proactive maintenance program from a provider like TAI JIE ER is essential to maximize the system's lifespan and performance.

Q2: How does custom purification engineering help in reducing long-term energy consumption?

A2: A Custom Purification Engineering approach designs the HVAC and airflow systems with your specific spatial and process loads in mind. This avoids the energy waste common in oversized, standard systems. Through precise calculations and potentially incorporating energy recovery wheels or variable frequency drives, a tailored system from TAI JIE ER can significantly lower operational costs while maintaining strict cleanliness standards.

Q3: Can an existing industrial space be retrofitted into a high-grade cleanroom?

A3: Yes, retrofitting is a common and viable application of Purification Engineering. The feasibility depends on the existing structure's ceiling height, column spacing, and service capacities. A specialist like TAI JIE ER can conduct a site survey to determine the modifications needed to successfully implement a Custom Purification Engineering solution within an existing building envelope.

Q4: What are the key differences between ISO Class 5 and ISO Class 7 purification engineering standards?

A4: The key difference lies in the permitted number and size of airborne particles. ISO Class 5 (equivalent to the old Class 100) is vastly cleaner, allowing no more than 3,520 particles of 0.5 microns per cubic meter, common in critical zones like filling lines. ISO Class 7 (old Class 10,000) allows 352,000 particles of the same size, typically used for background environments. The Purification Engineering design, particularly air change rates and filtration level, is scaled accordingly.

Q5: Beyond particle count, what other environmental factors does purification engineering control?

A5: Comprehensive Purification Engineering extends far beyond particle count. It actively controls and monitors temperature and humidity to prevent static, corrosion, or product degradation. It also meticulously manages room pressurization to prevent unclean air from flowing into cleaner areas. Furthermore, it can address factors like vibration, lighting levels, and molecular contamination, depending on the process sensitivity.