Simple Introduction

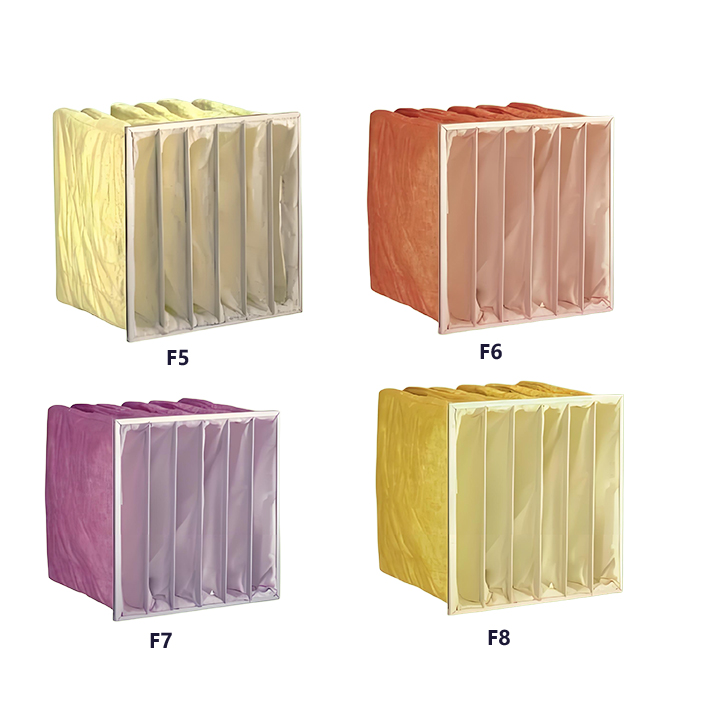

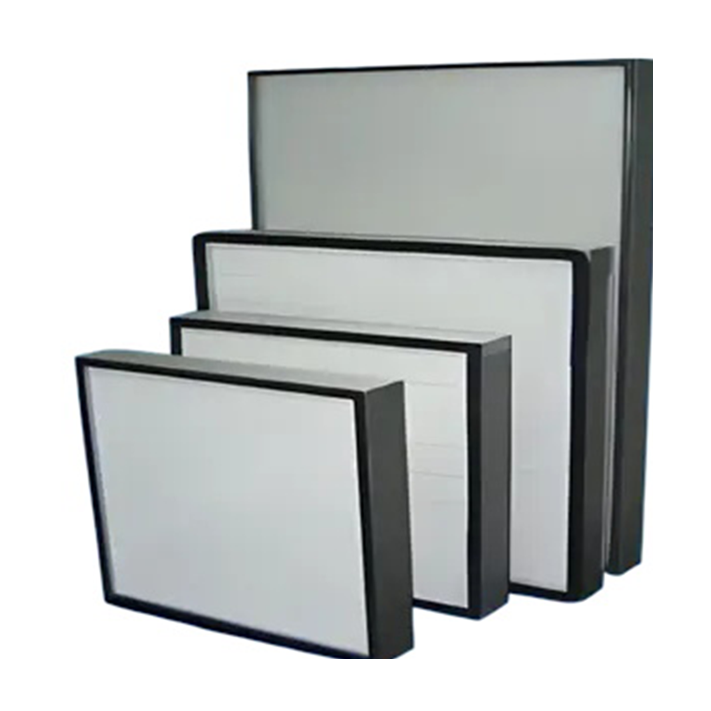

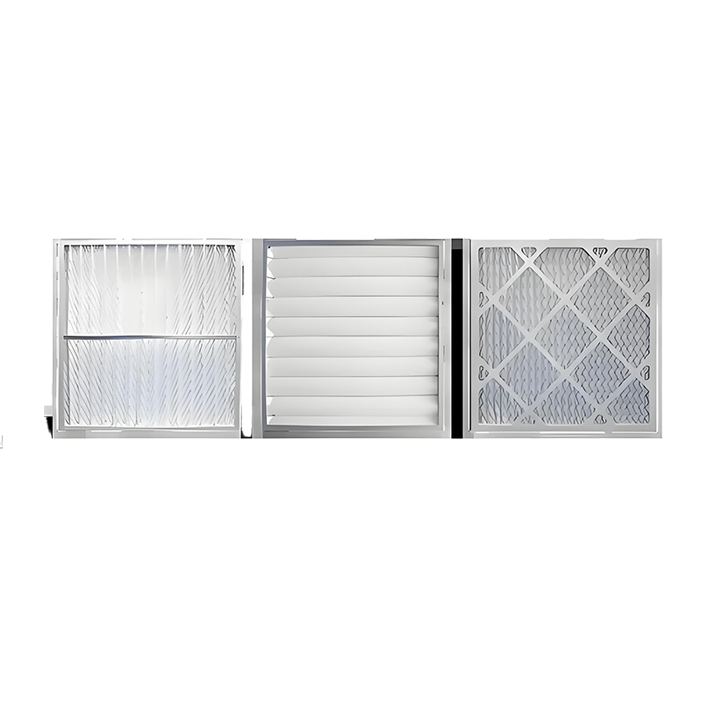

Primary efficiency filters are suitable for the initial filtration in air conditioning systems, mainly used to filter out dust particles larger than 5µm. The primary efficiency filters come in three types: panel, pleated, and bag types. The frame materials include paper frame, galvanized frame, and electro-galvanized iron frame. The filter media includes non-woven fabric, nylon mesh, activated carbon filter media, metal mesh, etc. Protective meshes include double-sided galvanized wire mesh and double-sided electro-galvanized iron wire mesh.

The nylon mesh filter adopts a lightweight plate structure, a reusable metal aluminum frame, and is woven from imported synthetic fibers. It has the characteristics of wear resistance, long service life, high strength, good comprehensive use effect, low initial resistance, strong dust resistance, multiple cleaning and reuse, and easy and safe replacement. Nylon mesh filters can be cleaned using compressed air or water containing cleaning agents to achieve reuse. The number of washable times is generally 1-2 times.

The initial effect plate folding filter is suitable for primary filtration in air conditioning systems, mainly used to filter dust particles larger than 5 μ m.

Detailed Introduction to Primary Efficiency Filters

Primary efficiency filters are characterized by low cost, light weight, good versatility, and compact structure.

Mainly used for:

• Pre-filtration of central air conditioning and centralized ventilation systems

• Pre-filtration of large air compressors

• Air purification and ventilation systems

• Pre-filtration of local high-efficiency filter installations

• High-temperature resistant air filters, using non-galvanized steel outer frames, with filtration efficiency at 250-300°C

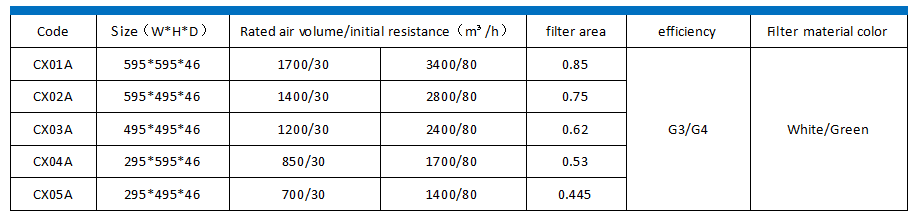

This filtration efficiency is often used as a pre-filter in air conditioning and ventilation systems and is also suitable for simple air conditioning and ventilation systems where only one stage of filtration is required. The G-series coarse efficiency air filters are divided into eight types: G1, G2, G3, G4, GN (nylon mesh filter), GH (metal mesh filter), GC (activated carbon filter), and GT (high-temperature coarse efficiency filter).

The frame of the filter is made of a solid waterproof board group, used to fix the pleated filter media. The frame is designed with beveled edges to provide a large filtration area and tightly attach the internal filter media to the outer frame. The four edges of the filter are sealed with a special professional adhesive to the outer frame to prevent air leakage or damage caused by wind pressure.

Single-use paper frame filters generally have frames made of regular cardboard and high-strength corrugated cardboard, with the filter media being pleated fiber filter media with a single-sided metal wire mesh backing. The appearance is neat and firm, and it is durable. Regular cardboard outer frames are used for manufacturing non-standard filters and can be applied to any size filter production. High-strength corrugated cardboard outer frames are used for standard filters with high dimensional accuracy, beautiful appearance, and low production cost. When using imported fiber or composite fiber filter media, their characteristic performance can generally reach or exceed imported filter equivalents.

Filter media are pleated into the frame with high-strength corrugated cardboard; this increases the effective area of the intake surface. Dust particles in the incoming air are effectively intercepted and trapped by the filter media. Clean air flows out evenly on the other side, so the airflow through the filter is even and smooth. Different filter media have different particle retention sizes ranging from 0 to 5µm, resulting in different filtration efficiencies!

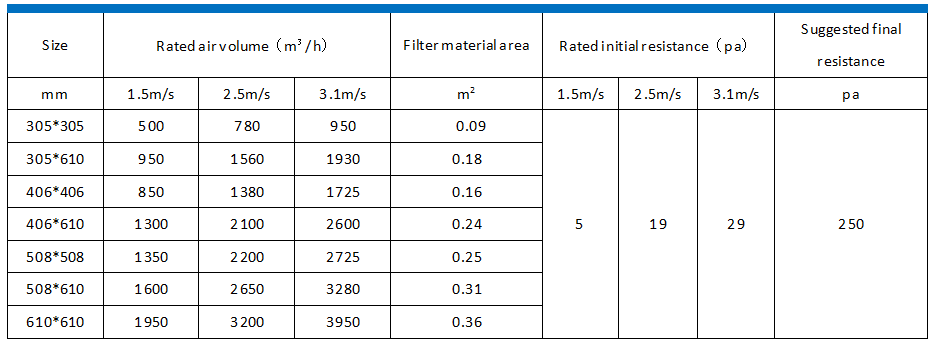

Primary Efficiency Filter Performance Parameters:

AAF AmNyl :

Initial effect plate folding filter: