Brief introduction

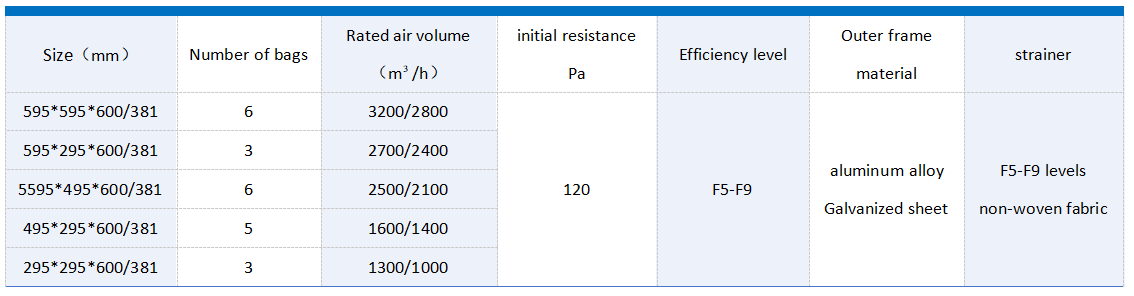

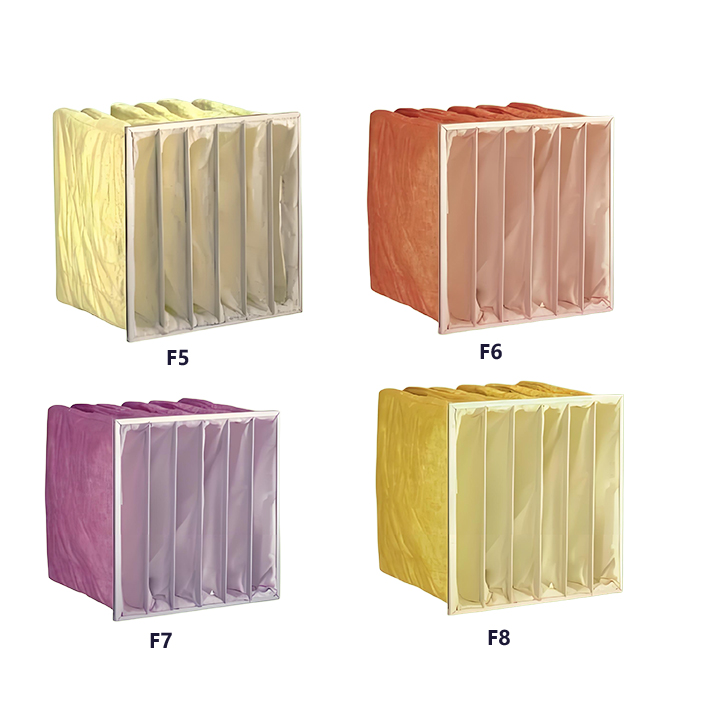

The medium efficiency filter is a type F air filter. Medium efficiency air filters of type F include two types: bag-type and non-bag-type. Among them, the bag-type includes F5, F6, F7, F8, and F9; the non-bag-type includes FB (medium efficiency panel filter), FS (medium efficiency separator panel filter), and FV (medium efficiency composite filter).

Detailed introduction to medium efficiency filters

Filtration principles of medium efficiency filters

1. Interception - Dust particles in the air move in an orderly or chaotic airflow or are affected by some external force to move. When small particles collide with other objects, Van der Waals forces (forces between molecules and molecular clusters) cause the particles to adhere to the fiber surface. In a medium efficiency filtration environment, small particles are more likely to collide with the medium and be retained. Small particles interact with each other through collisions, forming larger particles that settle. The color of walls and indoor furnishings in rooms is often related to this principle. Viewing filter fibers as traps is a misconception.

2. Inertia and diffusion - Dust particles moving with the airflow have inertia. When encountering disordered fibers in the filter, the airflow changes direction, causing the particles to deviate from their path. Larger particles are more likely to collide with the fibers and be retained, resulting in higher efficiency. Small particles move chaotically without clear patterns. The smaller the particles, the more chaotic their movement, increasing the chance of collision with obstacles and improving filtration efficiency. Particles smaller than 0.1 microns mainly move chaotically, so filtration efficiency is good. Particles larger than 0.3 microns mainly move due to inertia, and the larger the particle size, the higher the efficiency. Inertia and diffusion are not the decisive factors for the most difficult particles to filter. When measuring the efficiency of high-efficiency filters, the efficiency is often measured with the most difficult particles to filter.

3. Electrostatic effect - Due to certain reasons, fibers and small particles can carry static charges, generating an electrostatic effect. Filter materials with static charges can significantly improve filtration efficiency. The reason: static charges cause dust to change its trajectory and collide with obstacles. Dust is retained on the filter medium more effectively. Materials that maintain static charges for a long time are also called "electret" materials. Static charges do not change the filtration resistance but noticeably improve filtration efficiency. Static charges do not entirely determine filtration efficiency but play a supporting role. Medium efficiency filter.

4. Chemical filtration - Chemical filters mainly selectively absorb harmful gas molecules. Activated carbon materials have numerous micropores with a large adsorption surface area. Among activated carbon particles of different sizes, the micropore surface area can reach tens of square meters. When tiny gas molecules come into contact with activated carbon, they are adsorbed and retained on the surface through capillary action. Some bond with the material to form harmless solids or gases, known as chemical adsorption. During use, the adsorption capacity of activated carbon gradually decreases. When it drops to a certain level, the filter must be replaced. If only physical adsorption occurs, regeneration can be achieved by heating or steam to release the toxic gases and regenerate the activated carbon. The filter replacement time is typically 3-4 months under rated flow conditions; or when the filter resistance exceeds 400Pa, it must be replaced. If the filter uses washable material, it can be cleaned with clean water or a neutral alkaline solution and reinstalled; it can be washed up to 2 times before replacement is mandatory. If used in a dusty environment, the lifespan will be shorter.

4. Maintenance notes – Regularly inspect the filter to check if the surface is clogged or if the material is damaged. If the surface is clogged with dust, clean it; if the material is severely damaged, replace it or reinstall a new filter. When installing the filter, ensure the sealing between the frame and the filter to prevent air leakage; avoid hitting the filter surface with heavy objects; do not pull the filter surface forcefully; during installation, keep the filter bag opening vertical to the ground to ensure filtration efficiency and extend service life.

Common standards