Brief introduction

As an auxiliary equipment in clean rooms, transfer windows are mainly used for the transfer of small items between clean areas and clean areas, non clean areas and clean areas, in order to reduce the number of door openings in clean rooms and minimize pollution in clean areas. Transfer windows are widely used in micro technology, biological laboratories, pharmaceutical factories, hospitals, food processing industries LCD、 Electronic factories and all other places that require air purification.

The laminar flow transfer window is a specialized equipment used for the transfer of items in biological clean areas, which maintains an internal clean environment through laminar airflow control and efficient filtration systems. Its core design meets GMP standards, using a double-layer stainless steel shell, upper supply and lower return airflow mode, and electronic door interlock system to ensure sterile isolation during the transmission process.

core design

Filtering system: equipped with a combination of H14 high-efficiency filter and G4 primary efficiency filter, with a wind speed controlled at 0.36-0.57m/s (tested 150mm below the high-efficiency air flow plate).

Material: Inner and outer double-layer 304 stainless steel shell, surface polished treatment, frame thickness ≥ 1.2mm, visible window made of 8mm tempered glass.

Access control system: Double door interlock design, built-in UV lamp sterilization function, automatically opens sterilization mode when both doors are closed.

Functional Features

Cleanliness: Achieve B-level cleanliness standards (some models can reach A-level), with punched design and reinforced ribs at the bottom to ensure even airflow distribution.

Monitoring system: Real time display of filter pressure difference (accuracy ± 5Pa), equipped with pressure difference detection port and PAO detection port, supporting remote monitoring.

Maintenance convenience: The high-efficiency filter can be independently disassembled and replaced, and there is a maintenance port at the bottom for easy fan maintenance. The operating noise is below 65dB.

Application scenarios

It is mainly used in scenarios that require air purification, such as biopharmaceuticals, research institutions, and hospital clean areas, to replace frequent door opening and closing operations and reduce pollution risks.

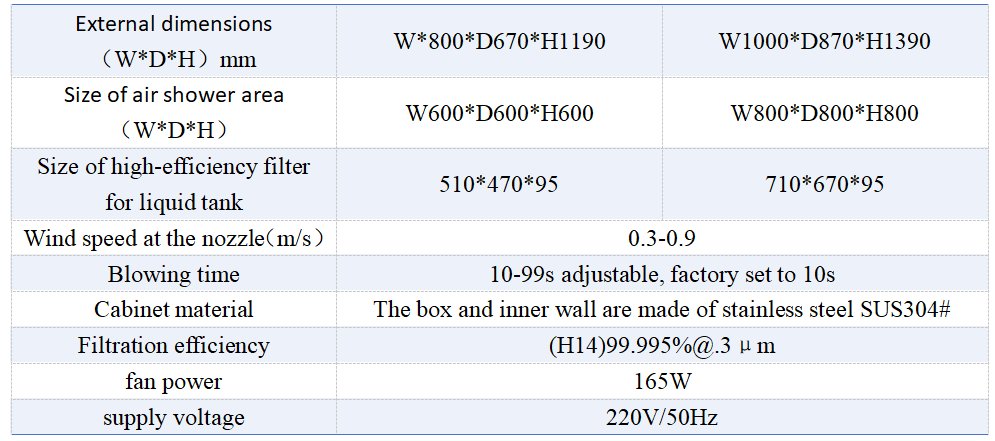

Technical Parameter: