Brief Introduction

Air shower transfer window is an auxiliary equipment in clean rooms, mainly used for the transfer of materials between clean areas and between clean areas, as well as between clean areas and non clean areas, in order to reduce the number of times the clean room is opened and minimize the pollution to the clean room.

Detailed introduction of air shower transmission window

The air shower transfer window consists of a box, a fan, a primary and high-efficiency filter, and other components. After the circulating air is filtered by the primary and high-efficiency filters, the airflow velocity sprayed out by the stainless steel nozzle can reach up to 20m/s, which can effectively and quickly remove dust particles attached to the surface of objects.

Wind shower transmission window equipment is widely used in industries such as electronics, microelectronics, semiconductors, liquid crystals, pharmaceuticals, biotechnology, optics, aerospace, etc.

Characteristics of air shower transmission window:

1.The entry and exit of materials in the clean area must be strictly separated from the pedestrian flow channel, and enter and exit through the dedicated channel for materials in the production workshop.

2.When two materials enter, the process leader of the preparation team organizes personnel to unpack or clean the surface of the raw materials, and then sends them to the temporary storage room of the workshop through the transfer window; After removing the outer packaging from the outer temporary storage room, the inner packaging materials are sent into the inner packaging room through the air shower transfer window. The workshop coordinator and the person in charge of the preparation and internal packaging processes handle the handover of materials.

3.When passing through the air shower transmission window, it is necessary to strictly follow the rule of "one opening, one closing" for the inner and outer doors of the air shower transmission window, and the two doors cannot be opened at the same time. Open the outer door to put the materials in, then close the door first, then open the inner door to take out the materials, and finally close the door, and repeat this process.

4.When materials are sent out from the clean area, they should be transported to the relevant material intermediate station first, and then removed from the clean area according to the reverse procedure of the materials entering.

5.All semi-finished products are transported from the clean area to the external storage room through the transfer window, and then transferred to the outer packaging room through the logistics channel.

6.Materials and waste that are highly prone to pollution should be transported from their dedicated air shower transfer windows to non clean areas.

7.After the completion of material entry and exit, the hygiene of each cleaning room or intermediate station and the transfer window should be cleaned in a timely manner, the internal and external passage doors of the transfer window should be closed, and cleaning and disinfection work should be done well.

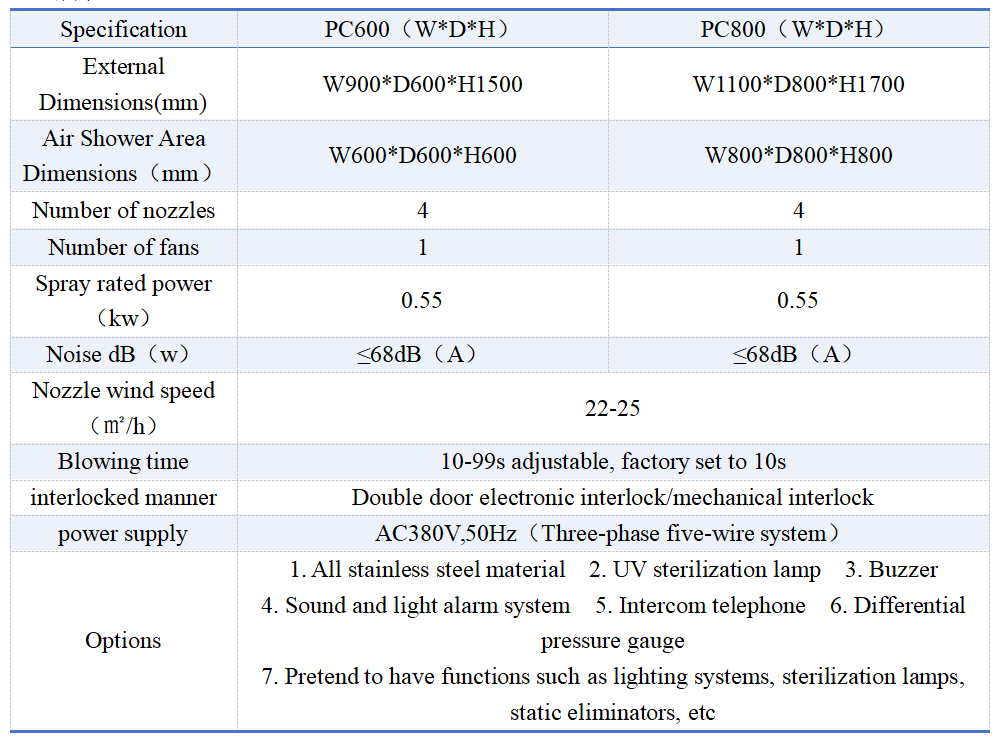

Technical Specifications: