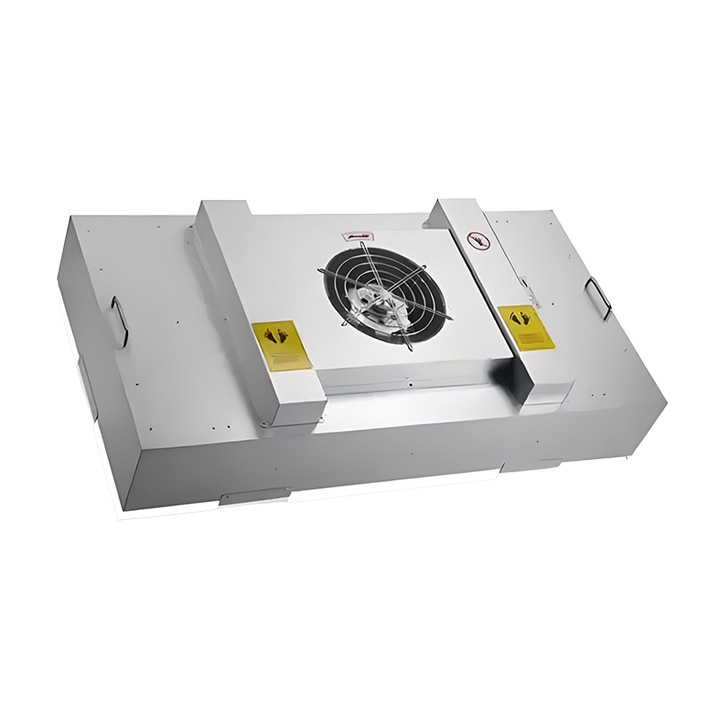

The FFU (Fan Filter Unit) is an automated motorized air filtration unit composed of a primary filter, a specialized fan, a high-efficiency filter, and a static pressure box. After air passes through the two-stage filtration system, clean air is blown out at an average wind speed of 0.45m/s ±20%. The FFU offers advantages such as low noise, low energy consumption, minimal vibration, adjustable speed, maintenance-free operation, and easy installation. It can be modularly assembled and connected for use, making it one of the most ideal air filtration devices for cleanrooms today.

Detailed Introduction to FFU

Fan Filter Unit (FFU)

The FFU (Fan Filter Unit) is an automated motorized air filtration unit composed of a primary filter, a specialized fan, a high-efficiency filter, and a static pressure box. After air passes through the two-stage filtration system, clean air is blown out at an average wind speed of 0.45m/s ±20%. The FFU offers advantages such as low noise, low energy consumption, minimal vibration, adjustable speed, maintenance-free operation, and easy installation. It can be modularly assembled and connected for use, making it one of the most ideal air filtration devices for cleanrooms today.

Application Scope:

Widely used in industries such as electronics, microelectronics, semiconductors, liquid crystal displays, pharmaceuticals, biotechnology, optics, aerospace, and more. It can be configured into cleanrooms, clean production lines, clean assembly rooms, and various applications with different cleanliness levels.

Product Features:

Reliable Efficiency

Equipped with a high-efficiency, domestically produced specialized fan, the FFU delivers top-tier quality, excellent stability, low energy consumption, and a working lifespan of up to 100,000 hours, significantly reducing production and usage costs for customers.

Easy Installation and Flexibility

No regional limitations; can be independently controlled by zone. Lightweight and ultra-thin body design makes the FFU suitable for various environments, especially for factory cleanroom renovations.

High Airflow, Low Noise

Features a scientifically selected fan, optimized speed design, unique air guidance, and static pressure box design, as well as a rational body structure, ensuring high airflow efficiency and low noise.

Safety Protection

Uses a three-speed variable frequency adjustment to meet different customer airflow needs. The integrated main controller includes thermal protection, overload protection, and overvoltage protection, ensuring safety and reliability.

Modular Design

Standardized modular design with high compatibility, allowing configuration into high-end cleanroom production lines, Class 100 cleanrooms, dust-free cabinets, and cleanrooms ranging from thousands to tens of thousands of cleanliness levels.

Custom Design

In addition to standard sizes, custom production is available to meet various customer requirements.

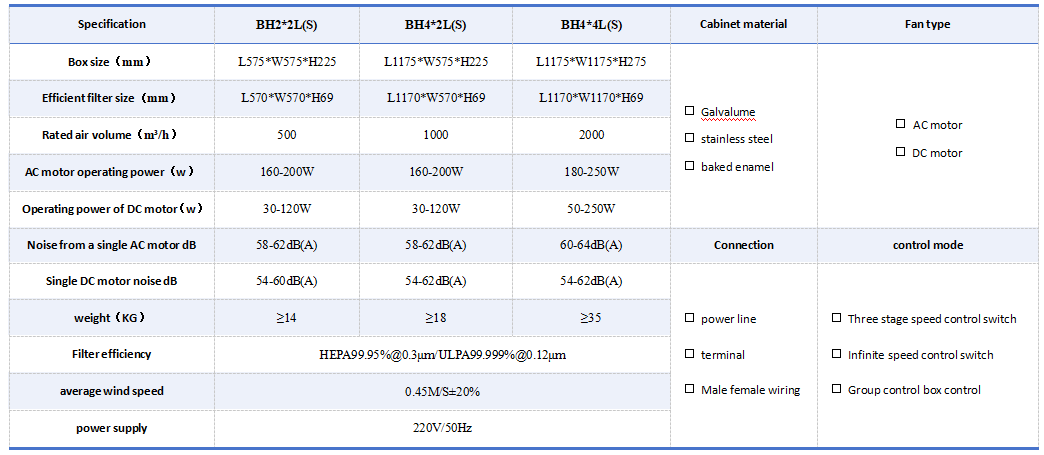

Technical Specifications: