Simple introduction

Cargo shower room is a necessary passage for goods to enter the cleanroom. It can reduce contamination issues caused by goods entering the cleanroom and is an essential cleaning device.

Detailed introduction to the goods air shower

The goods air shower has two interlocked electronic doors and can function as an airlock, preventing uncleaned air from entering the cleanroom and reducing contamination caused by goods during their passage. When goods enter the air shower, high-speed clean air is effectively filtered through a high-efficiency filter and then blown from rotating nozzles in multiple directions onto the surface of the goods, quickly and effectively removing dust particles. The air carrying dust is then recirculated back to the air shower area after passing through primary and high-efficiency filters.

Key points for maintaining the goods air shower:

1. Regularly use technical standards to inspect the filters and address any issues promptly if standards are not met.

2. Depending on actual usage, periodically remove and clean the primary filter.

3. If wind speed decreases, first check if the primary filter surface is blackened. If so, it indicates excessive dust accumulation, increasing resistance. Clean or replace the primary filter.

4. If wind speed does not improve after adjusting or cleaning the primary filter, the high-efficiency filter may be clogged and needs replacement.

5. When replacing the high-efficiency filter, remove the nozzle panel, take out the old filter, and install a new one of the same specifications. Ensure the airflow direction arrow on the filter is correctly aligned and the seal is tight to prevent air leaks.

6. After replacement, check for frame leaks and use a particle counter to verify compliance with technical standards before normal operation.

7. Regularly inspect and maintain electrical and pneumatic lines, referring to schematic diagrams if issues arise.

8. Periodically check and maintain doors to ensure electronic locks function correctly, preventing mislocking or failure to open.

9. The operating temperature of the goods air shower must not exceed 50°C, and open flames are strictly prohibited.

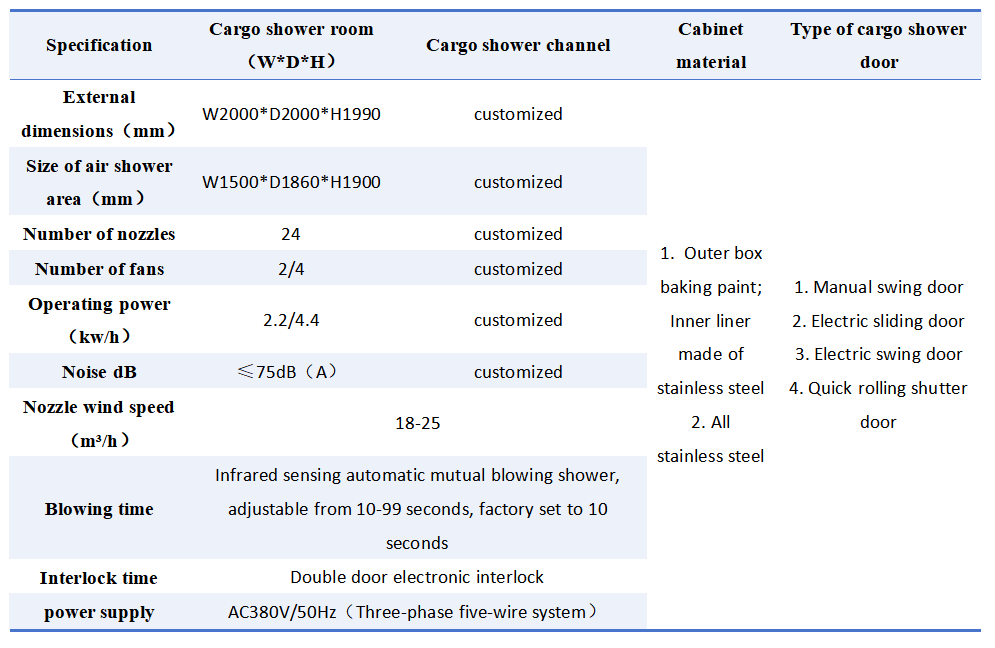

Technical specifications: